Laser Welding Machines: A Brief Overview

Laser welding has emerged as a revolutionary technology in modern manufacturing, offering unparalleled precision and efficiency in joining various materials. This article provides a comprehensive overview of laser welding machines, exploring their fundamental principles, key advantages, diverse applications, and crucial considerations for selection and use.

What is a Laser Welding Machine?

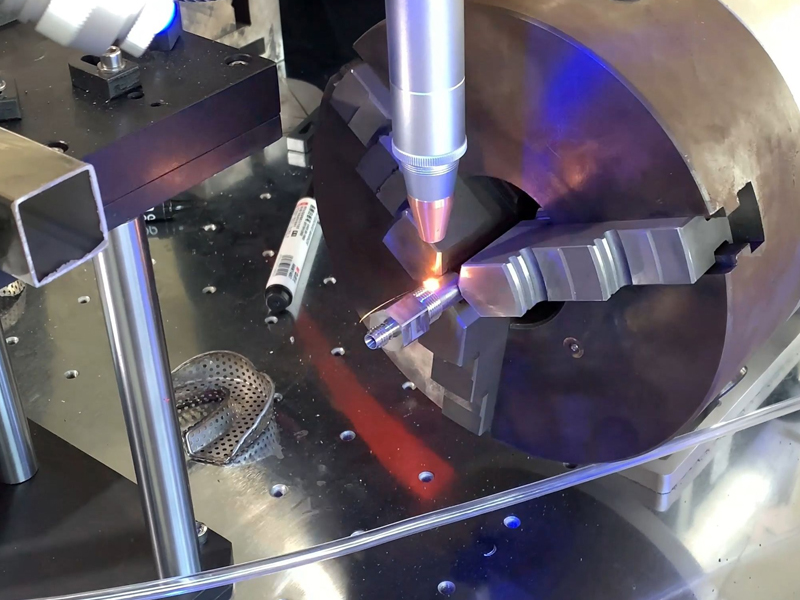

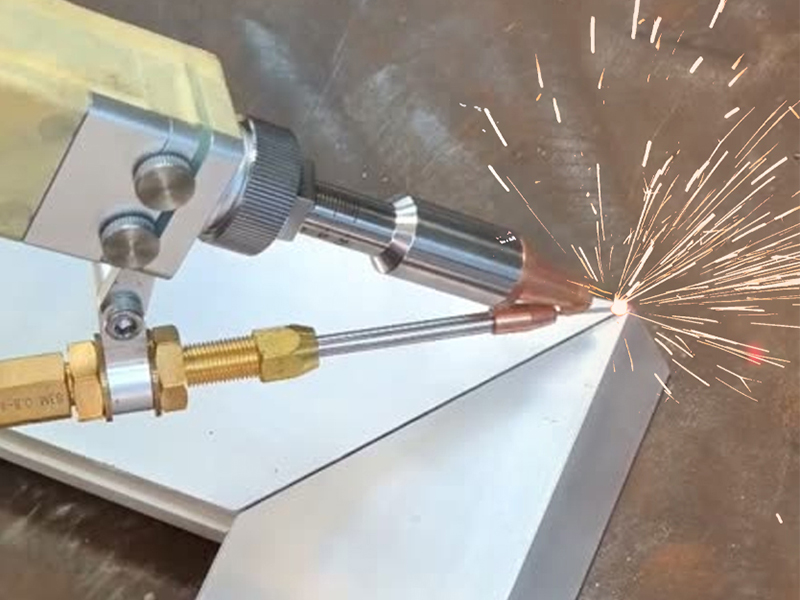

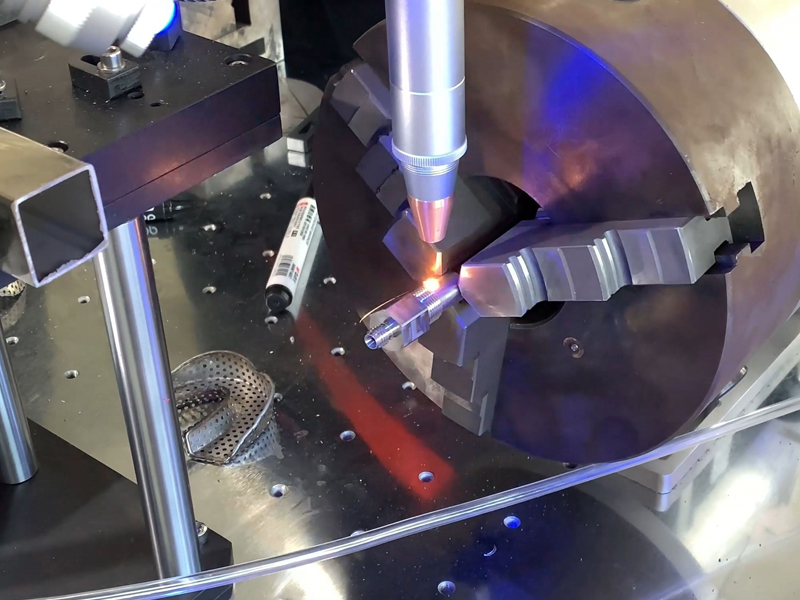

A laser welding machine, also known as a laser welder or laser welding apparatus, is a machine used for laser material processing. It is a precision device that utilizes a high-power laser beam to generate localized heat for joining materials. Characterized by high efficiency, precision, and high-quality welding, laser welding differs from traditional welding methods in that it employs a focused beam of light, enabling precise control over the welding process and minimizing heat input to the surrounding material.

How does a Laser Welding Machine Work?

The core principle of laser welding lies in the conversion of optical energy into thermal energy. The laser welding machine generates a highly concentrated beam of coherent light, typically from a solid-state laser or a fiber laser. This beam is then directed onto the workpiece, where it is absorbed by the material. The absorbed energy rapidly heats the material at the focal point, causing it to melt and form a weld pool.

The welding process can be further enhanced through various techniques, such as pulse welding, continuous wave welding, and keyhole welding. Pulse welding delivers short bursts of laser energy, suitable for delicate materials. Continuous wave welding provides a steady stream of laser energy for continuous welding operations. Keyhole welding creates a narrow, deep penetration in the material, ideal for welding thicker materials.

Advantages of Laser Welding

Laser welding offers several significant advantages over traditional welding methods:

High Precision

The laser beam has a very small spot size, enabling highly precise welding. For products with stringent welding precision requirements, such as electronic components and medical devices, laser welding machines are the ideal choice.

High Speed

Laser welding is a high-speed process that significantly improves production efficiency. Compared to traditional welding methods, laser welding can complete a large volume of welding work in a short period.

Small Heat-Affected Zone (HAZ)

The heat-affected zone in laser welding is very small, resulting in minimal thermal damage to the material. This means that the material properties after welding change less, maintaining good mechanical properties and appearance.

Versatility

Laser welding machines can weld a variety of materials, including metals, plastics, and ceramics. By adjusting the laser parameters, different materials can be welded.

High Degree of Automation

Laser welding machines can be integrated with automated equipment to achieve automated production. This not only improves production efficiency but also reduces labor costs and intensity.

Applications of Laser Welding

Widely used in the automotive, electronics, medical, and aerospace industries, laser welding machines are advanced welding equipment known for their high precision, speed, and minimal heat-affected zone.

Automotive Manufacturing: Laser welding machines have found widespread application in automotive manufacturing, such as in body welding, engine component welding, and automotive electronics assembly. Through laser welding machines, the welding precision and efficiency in automotive manufacturing have been significantly improved.

Aerospace: In the aerospace industry, laser welding machines are used to manufacture high-precision components and structural parts. For example, the landing gear of an aircraft uses laser welding technology, greatly improving the stability and safety of the landing gear.

Electronics Assembly: Laser welding machines play a crucial role in electronics assembly, such as in the connection of motherboards and component assembly of products like mobile phones, computers, and tablets. Due to the high precision and speed of laser welding, it can meet the requirements of the electronics industry for welding quality and production efficiency.

Medical Device Manufacturing: In medical device manufacturing, laser welding technology is widely used in the manufacturing of high-precision medical devices such as surgical instruments and diagnostic equipment.

Other Industries: Laser welding machines can also be applied in fields such as hardware products, jewelry, and mold manufacturing.

Considerations for Selecting and Using Laser Welding Machines

Choosing the right laser welding machine is crucial for boosting productivity and competitiveness in today’s manufacturing landscape. However, the process of purchasing and effectively using such a machine requires careful evaluation from various angles.

- Selecting the Appropriate Laser Welding Machine: Choose a laser welding machine based on factors such as welding materials, welding requirements, and production scale. Different types of laser welding machines have different characteristics and application ranges, so the selection should be based on specific needs.

- Operator Training: Laser welding machines are high-tech equipment that requires professional operators. Before using a laser welding machine, operators should be trained to familiarize themselves with the equipment’s operation methods and safety precautions.

- Safety Precautions: Laser welding machines produce high-energy laser beams that can be harmful to the human body. When using a laser welding machine, necessary safety precautions should be taken, such as wearing protective glasses and gloves.

- Maintenance and Servicing: Regularly maintain and service the laser welding machine to ensure its normal operation. Maintenance and servicing include cleaning the equipment, inspecting the optical system, and replacing consumable parts.

With the continuous advancement of technology, laser welding machines have played an increasingly important role in modern manufacturing. Their high precision, high speed, ease of operation, and wide range of applications in various fields have demonstrated their advantages. At the same time, the pollution-free, material-damage-free, and stable quality characteristics of laser welding machines have made them a precise tool for modern manufacturing.

As a leading laser welding machine manufacturer, Zixu provides a comprehensive range of high-quality laser welding solutions, serving industries from aerospace to jewelry. We offer both standardized and tailored laser welding machines to meet our customers’ unique requirements.

Recommended Products