Максимально эффективная работа с гравером Dot Peen

Точечные граверы стали незаменимыми инструментами в различных отраслях промышленности, обеспечивая точность, долговечность и универсальность при нанесении маркировки. Понимая ключевые особенности, сферы применения и требования к обслуживанию этих граверов, предприятия могут оптимизировать их работу и обеспечить долговечность. Компания Zixu представит граверы для точечной гравировки и расскажет о возможностях настольных пневматических моделей. Это руководство поможет пользователям максимально использовать потенциал своих граверов, начиная с их универсального применения и заканчивая основными методами технического обслуживания.

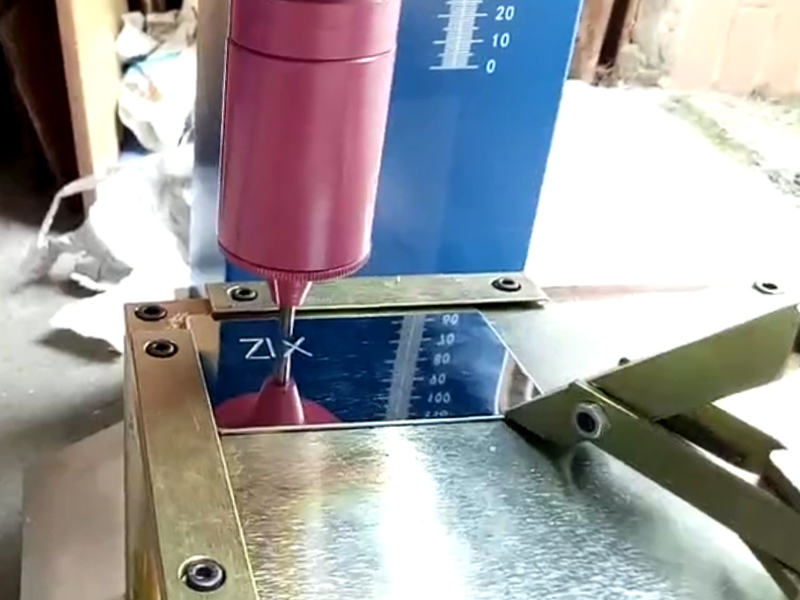

Особенности настольного пневматического гравера

Настольный пневматический точечный гравер - это универсальный инструмент, предназначенный для точной и эффективной маркировки широкого спектра материалов. Он обладает рядом ключевых характеристик, которые делают его незаменимым помощником в различных отраслях промышленности:

- Широкая совместимость: Гравер поддерживает различные графические и шрифтовые форматы, обеспечивая беспрепятственную интеграцию с популярными программами проектирования, такими как AutoCAD и CorelDraw. Такая совместимость позволяет пользователям легко импортировать и обрабатывать свои проекты для маркировки.

- Интеллектуальное управление: Оснащенный системой запросов к центру обработки данных и функцией печати интеллектуальных отчетов, этот гравер упрощает управление данными и ведение учета. Пользователи могут легко получать и анализировать данные о печати, что повышает степень отслеживания и контроля качества.

- Высокая точность: Гравер обеспечивает исключительную точность маркировки, достигая точности до миллиметра. Это обеспечивает четкую и последовательную маркировку, отвечающую строгим требованиям различных областей применения.

- Широкий диапазон применения: Помимо печати символов, серийных номеров и VIN-кодов, гравер может также создавать штрих-коды и QR-коды. Благодаря своей универсальности он подходит для решения широкого спектра задач по маркировке, от идентификации продукции до отслеживания активов.

- Портативность: Компактная и портативная конструкция обеспечивает удобство транспортировки и эксплуатации в различных рабочих условиях. Такая гибкость повышает производительность и удобство.

Настольные пневматические граверы для точечной гравировки идеально подходят для работ, требующих долговечной и разборчивой маркировки на металле, пластике и других твердых материалах. Сочетание точности, универсальности и простоты использования делает их ценным инструментом для таких отраслей, как автомобильная, аэрокосмическая, электронная и обрабатывающая промышленность.

Области применения настольных пневматических точечных граверов

Настольные пневматические граверы для точечной гравировки нашли широкое применение в различных отраслях промышленности благодаря своей способности наносить маркировку на широкий спектр материалов с точностью и долговечностью. Некоторые из основных областей применения включают:

- Автомобильное производство: В автомобильной промышленности эти граверы широко используются для маркировки компонентов двигателя, шасси, ходовой части и других деталей идентификационными номерами, именами, логотипами и датами производства. Постоянная и разборчивая маркировка обеспечивает прослеживаемость и соответствие промышленным стандартам.

- Машиностроение: Настольные пневматические точечные граверы - это бесценный инструмент для маркировки различных механических компонентов, станков и аппаратных изделий. Они могут использоваться для маркировки номеров деталей, размеров и спецификаций материалов, облегчая управление запасами и контроль качества.

- Производство электроники: В электронной промышленности эти граверы используются для нанесения серийных номеров, номеров моделей и другой важной информации на электронные компоненты и узлы. Маркировка обеспечивает прослеживаемость и помогает предотвратить подделку.

- Изготовление металлических изделий: Настольные пневматические граверы для точечной гравировки идеально подходят для маркировки металлических изделий, таких как трубы, шестерни, корпуса насосов и клапаны. Они могут создавать долговечную и разборчивую маркировку на различных металлах, включая сталь, алюминий и нержавеющую сталь.

Настольные пневматические точечные граверы - это универсальное и эффективное решение для маркировки, требующей постоянной, разборчивой и долговечной маркировки. Способность работать с широким спектром материалов и наносить высококачественную маркировку делает их незаменимым инструментом во многих отраслях промышленности.

Рекомендации по техническому обслуживанию и уходу за настольными пневматическими граверами Dot Peen

Настольный пневматический точечный гравер, являясь прецизионной машиной, требует регулярного обслуживания для обеспечения оптимальной производительности и долговечности. Ниже приведены некоторые основные рекомендации по обслуживанию и уходу:

| Подготовка к охране окружающей среды | Перед началом работы с гравером подготовьте чистое и незагроможденное рабочее место. Убедитесь, что гравер надежно подключен, давление воздуха в системе питания достаточное, а электропитание стабильное. |

| Предоперационная проверка | Перед запуском гравера проверьте машину на наличие пыли и мусора. Убедитесь, что содержание маркировки является точным и соответствует требуемым параметрам. Убедитесь, что давление воздуха находится в заданном диапазоне и что заготовка надежно зажата. |

| Ежедневное обслуживание | Ежедневно очищайте гравер, уделяя особое внимание удалению мелкого мусора, особенно из компонентов трансмиссии. Регулярная смазка системы передачи (оси X, Y и Z) имеет решающее значение для продления срока службы гравера. |

| Периодическое обслуживание | Если граверы не используются постоянно, запускайте их на 1-2 часа каждую неделю, чтобы обеспечить циркуляцию воздуха в системе управления и предотвратить накопление влаги, которая может повредить электронные компоненты. |

| Поиск и устранение неисправностей и техническое обслуживание | Если вы столкнулись с какими-либо проблемами, например, с уменьшением глубины или ширины маркировки, возможно, необходимо заменить изношенную маркировочную иглу. Если маркировочная игла не выдвигается или выдвигается ненормально, проверьте регулятор давления и убедитесь, что линии подачи воздуха подключены правильно. |

| Обслуживание электрических систем | Регулярно осматривайте электрическую систему, включая шнуры питания, разъемы и выключатели, на предмет наличия признаков повреждений. Очищайте внутреннюю поверхность электрического шкафа, чтобы предотвратить скопление пыли, которая может привести к электрическим неисправностям. |

| Обслуживание программного обеспечения | Программное обеспечение является неотъемлемой частью работы гравера. Регулярно обновляйте систему числового программного управления и программное обеспечение для обеспечения оптимальной производительности. Регулярно создавайте резервные копии параметров системы и программ, чтобы предотвратить потерю данных. |

Освоение граверов

Настольные пневматические граверы для точечной гравировки - это бесценный инструмент для предприятий, стремящихся к точности, долговечности и универсальности в области маркировки. Понимая основные характеристики, области применения и требования к обслуживанию, пользователи могут оптимизировать их работу и обеспечить долговременную ценность. Следуя рекомендациям, изложенным в этой статье точечный гравер поставщик Компания ZixuПредприятия могут максимально использовать потенциал своих точечных граверов, добиваясь эффективности операций, повышения контроля качества и улучшения отслеживаемости. При надлежащем уходе и обслуживании эти граверы могут продолжать обеспечивать исключительные результаты в течение многих лет.

Recommended Products