Машины для нанесения надписей: Знак точности и эффективности

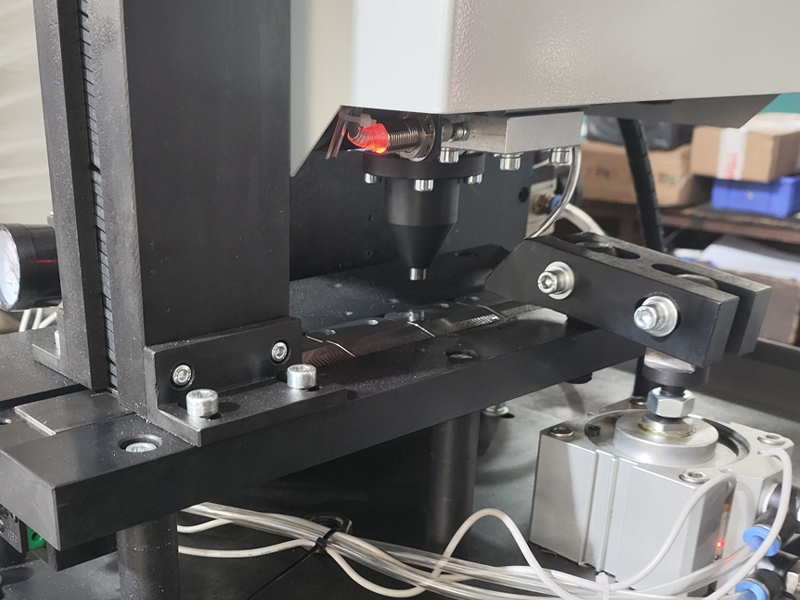

гравировальный станок стали незаменимыми инструментами в различных отраслях промышленности, обеспечивая надежный и эффективный метод создания постоянных высококачественных меток на широком спектре материалов. Эти машины сочетают в себе точность, универсальность и долговечность, что делает их идеальными для применения в тех областях, где требуется точная и последовательная идентификация, отслеживание или брендирование. Компания Zixu познакомит вас с миром маркировочных машин, расскажет об их преимуществах, областях применения и факторах, которые необходимо учитывать при выборе машины для ваших конкретных нужд. Это руководство поможет вам принять обоснованное решение и оптимизировать процессы маркировки, начиная с понимания различных типов машин и заканчивая оценкой их возможностей.

Преимущества использования маркировочной машины

Постоянные следы

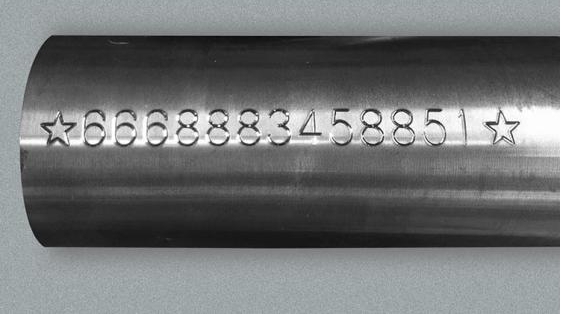

- Долговечность: Насечки очень устойчивы к истиранию, поэтому они практически не подвержены износу.

- Химическая стойкость: Они не подвержены воздействию большинства химических веществ, что гарантирует сохранение четкости и разборчивости маркировки даже в суровых условиях.

- Экологическая долговечность: Маркировка устойчива к атмосферным воздействиям, включая перепады температур, влажность и ультрафиолетовое излучение, что обеспечивает ее долговечность на открытом воздухе.

- Долгосрочная читаемость: Маркировочные знаки рассчитаны на многолетний срок службы, что делает их идеальными для применения в тех случаях, когда важна постоянная идентификация.

Универсальность

- Широкий выбор материалов: Машины для нанесения надписей могут эффективно маркировать различные материалы, включая металлы, пластик, керамику, стекло и даже некоторые породы дерева.

- Адаптация к различным поверхностям: Они могут работать как с плоскими, так и с изогнутыми поверхностями, что делает их универсальными для различных задач маркировки.

- Настраиваемая маркировка: Машины для нанесения надписей могут создавать отметки на различных материалах, независимо от их твердости и текстуры поверхности.

Гибкость

- Сложные маркировки: Машины для нанесения надписей могут быть запрограммированы на создание сложных и детальных надписей, включая текст, цифры, штрих-коды и логотипы.

- Варианты настройки: Пользователи могут легко настраивать внешний вид своих знаков, регулируя размер шрифта, интервал и другие параметры в соответствии с конкретными требованиями.

- Интеграция с другими системами: Многие маркировочные машины могут быть интегрированы с другими производственными системами, такими как станки с ЧПУ или автоматизированные сборочные линии, для эффективной и рациональной работы.

Высокая точность

- Точная маркировка: Машины для нанесения надписей способны создавать высокоточные и последовательные знаки, обеспечивая четкую читаемость и легкость идентификации информации.

- Повторяемость: Машины могут надежно воспроизводить одни и те же знаки снова и снова, обеспечивая постоянство и контроль качества.

- Приверженность толерантности: Станки для нанесения надписей могут соответствовать жестким допускам, что делает их подходящими для применения в тех случаях, когда точность очень важна.

Области применения маркировочных машин

Машины для нанесения надписей имеют широкий спектр применения в различных отраслях промышленности. Вот некоторые из них:

Производство

- Идентификация детали: Маркировка номеров деталей, серийных номеров или другой идентифицирующей информации на компонентах.

- Контроль качества: Маркировка точек контроля или информации о контроле качества.

- Прослеживаемость: Информация о маркировке для отслеживания компонентов в процессе производства.

- Маркировка штрих-кодов и QR-кодов: Создание штрих-кодов или QR-кодов для управления запасами и отслеживания данных.

Промышленное оборудование

- Отслеживание активов: Нанесение идентификационных номеров на оборудование для отслеживания и обслуживания.

- Калибровочные метки: Маркировка точек калибровки на измерительных приборах.

- Предупреждающие этикетки: Нанесение предупреждений о безопасности или символов опасности на оборудование.

Автомобильная промышленность

- Идентификация автомобиля: Маркировка VIN-номеров, номеров двигателей и другой идентифицирующей информации на автомобилях.

- Отслеживание компонентов: Маркировка информации на компонентах для отслеживания их происхождения и истории.

- Контроль качества: Маркировка точек контроля на автомобильных деталях и узлах.

Аэрокосмическая промышленность

- Отслеживание компонентов: Нанесение идентификационных номеров на компоненты самолета для отслеживания и обслуживания.

- Маркировка безопасности: Нанесение предупреждений о безопасности или символов опасности на детали самолета.

- Калибровочные метки: Обозначение точек калибровки на авиационных приборах.

Какие существуют различные типы маркировочных машин?

| Характеристика | Ручной писец маркировки машины | Интегрированный писец маркировки машины |

| Мобильность | Точность может варьироваться в зависимости от квалификации оператора | Стационарные, обычно интегрированные в производственную линию |

| Сложность маркировки | Подходит для нанесения простых меток и мелких деталей | Возможность создания сложных знаков, включая штрих-коды, логотипы и подробный текст |

| Операция | Точность может варьироваться в зависимости от квалификации оператора | Автоматизированная работа, часто управляемая компьютером |

| Объем производства | Подходит для малых и средних объемов производства | Идеально подходит для крупносерийного производства |

| Точность | Высокая мобильность позволяет использовать его в различных местах | Как правило, обеспечивает более высокую точность и воспроизводимость |

| Гибкость | Менее гибкие в плане программирования и настройки | Высокая гибкость, легко программируется для различных задач маркировки |

Факторы, которые следует учитывать при выборе маркировочного станка

Сложность маркировки

- Простые знаки: Ручные станки хорошо подходят для нанесения простых меток на небольшие детали, таких как номера деталей, серийные номера или основные логотипы. Они представляют собой экономичное и портативное решение для небольших объемов работ.

- Комплекс Marks: Integrated scribe machines are equipped with advanced software and hardware that enable them to create complex marks, including barcodes, QR codes, and intricate designs. These machines are ideal for high-volume production and applications requiring precise and detailed markings.

Объем производства

- Малосерийное производство: Ручные машины подходят для мелкосерийного производства, поскольку они обеспечивают гибкость и зачастую более доступны по цене.

- Крупносерийное производство: Интегрированные писчебумажные машины предназначены для крупносерийного производства, обеспечивая автоматизацию, скорость и эффективность. Они позволяют значительно повысить производительность и снизить трудозатраты.

Требования к точности

- Умеренная точность: Ручные станки могут обеспечить достаточную точность для многих применений. Однако если вам требуется высокая точность и стабильность маркировки, рекомендуется использовать интегрированный станок с компьютерным управлением.

- Высокая точность: Интегрированные машины оснащены передовыми системами управления, которые обеспечивают точность и повторяемость маркировки. Они идеально подходят для тех областей применения, где важна точная идентификация или прослеживаемость.

Бюджет

- Первоначальная стоимость: Ручные машины обычно имеют более низкую первоначальную стоимость по сравнению с интегрированными машинами. Однако интегрированные машины могут обеспечить долгосрочную экономию средств за счет повышения эффективности и автоматизации.

- Текущие расходы: При оценке общей стоимости владения учитывайте такие факторы, как техническое обслуживание, эксплуатационные расходы (например, электроэнергия, расходные материалы) и обучение оператора.

Мастерство оператора

- Ручные машины: Управление ручной маркировочной машиной требует определенного уровня мастерства и точности. Оператор должен иметь твердую руку и уметь точно управлять стилусом.

- Интегрированные машины: Интегрированные машины зачастую проще в эксплуатации, поскольку они оснащены удобными интерфейсами и функциями автоматизации. Это позволяет сократить необходимость в длительном обучении оператора.

Гибкость

- Ручные машины: Ручные станки обеспечивают определенную гибкость, поскольку их можно использовать в разных местах и для разных задач маркировки. Однако они могут иметь ограничения по программированию и настройке.

- Интегрированные машины: Интегрированные машины отличаются высокой гибкостью и легко программируются для создания широкого спектра маркировок. Они идеально подходят для тех областей применения, где требуется часто менять требования к маркировке.

Точность и эффективность

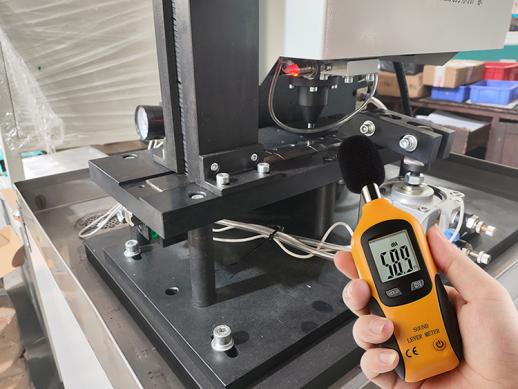

Машины для нанесения надписей произвели революцию в способах маркировки и идентификации изделий, компонентов и оборудования в различных отраслях промышленности. Их способность создавать постоянные, точные и универсальные метки сделала их незаменимыми инструментами для производителей, инженеров и специалистов по контролю качества.

Внимательно изучив преимущества, области применения и факторы, которые следует учитывать при выборе маркировочной машины, вы сможете выбрать наиболее подходящий вариант для ваших конкретных нужд. Независимо от того, нужна ли вам ручная машина для периодического использования или интегрированная система для крупносерийного производства, маркировочные машины от Компания Zixu предлагают надежное и эффективное решение для ваших требований к маркировке.

Recommended Products