Wood & Bamboo Laser Application

In recent years, the use of lasers for cutting, engraving and marking wood and bamboo has become a mainstream technology as CO2 laser cutting machines continue to decrease in price and popularity. Compared with the common CO2 laser cutting machines such as 6040, 1360, 1390, etc., we specialize in high precision, complex shapes and automated solutions for wood and bamboo products using CO2 galvanometer marking machines and UV laser systems.

Technologies For Wood & Bamboo

Laser marking, engraving or cutting of wood or bamboo products requires no physical contact, resulting in less noise and debris than traditional sawing or grinding processes, and smooth, burr-free edges without the need for sanding. Laser marking machines require no consumables such as marking needles, can be installed and operated under heavy loads for long periods of time, require only periodic calibration to maintain consistent marking quality and efficiency, and are easy to automate.

- Quiet: laser systems also produce noise, but this is negligible compared to a saw or grinding wheel;

- Accuracy: lasers can mark and engrave characters and images on very small sizes of wood or bamboo products with line widths as small as 0.03mm;

- Visibility: laser marking can leave high-contrast, scannable dates, logos, serial numbers, bar codes, etc. on wood or bamboo products.

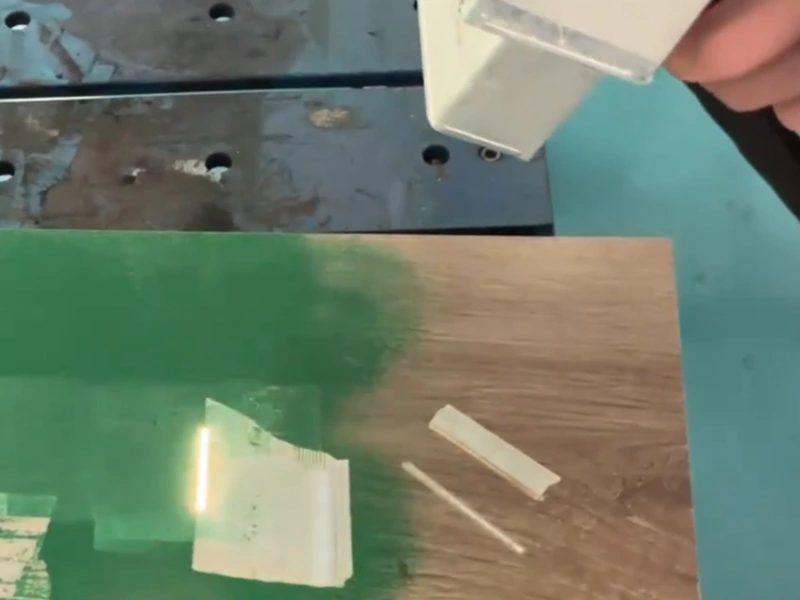

Laser cleaning is more efficient and sustainable than ultrasonic or detergent cleaning due to its non-contact nature, and has been used to clean antique wooden buildings and artifacts since the 1970s. In recent years, with the development and price reduction of the MOPA fiber laser and various UV lasers, the use of laser cleaning to effectively clean or remove dirt, oil, paint or coatings from wood surfaces has become increasingly popular.

- Efficient: the high-energy laser beam vaporizes contaminants in a very short time with minimal damage to the workpiece.

- Precision: the extremely small spot size of the laser beam allows precise control of the position and depth of the cleaning process.

- Easily automated: the laser beam removes oil, grease, paint and coatings over long distances, and its simple design makes it suitable for automated cleaning.

Explore Our Machines For Wood & Bamboo

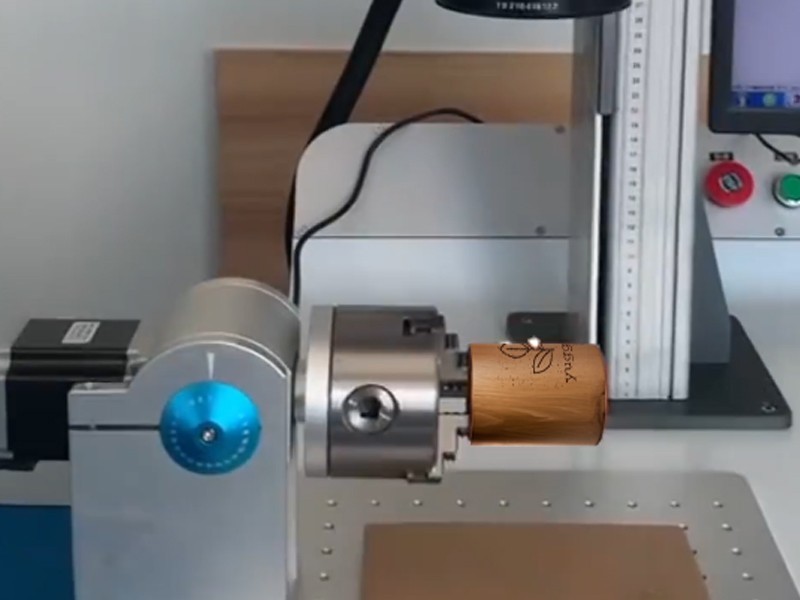

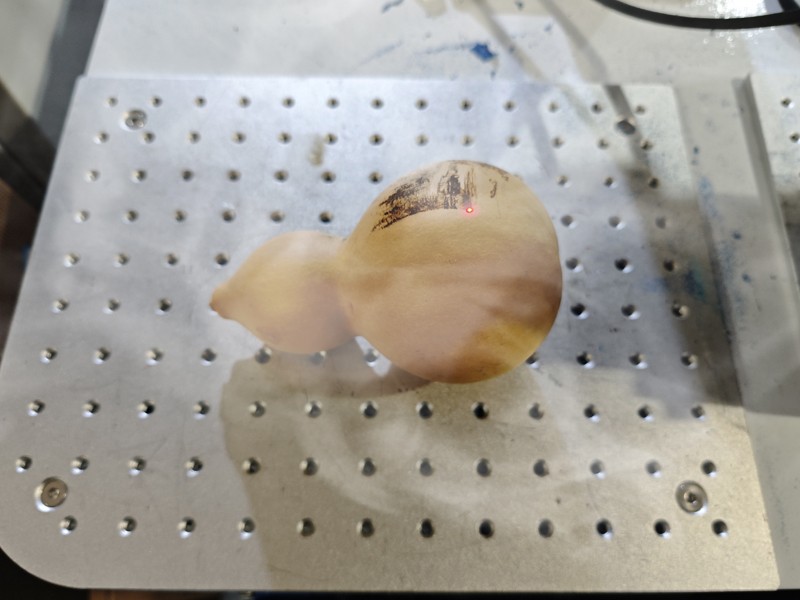

CO2 laser marking has been widely used as an alternative to ink printing, especially for all kinds of wood and bamboo crafts, household and decorative items, etc. It can be used to permanently mark brand logos, patterns and all kinds of text information. Although it can’t reach the pure black color like ink, it still has the characteristics of high contrast and not easy to wear. Compared with CO2 laser cutting machine, we are better at using galvanometer marking machine to realize more complex appearance of workpieces.

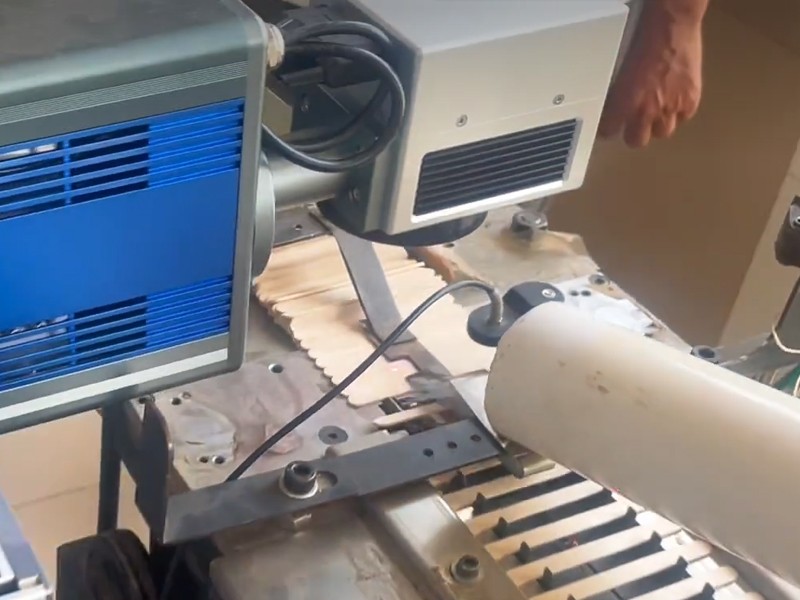

Shaker-type CO2 laser markers are better than cutters for accurate marking of small areas. Using a CO2 laser to mark bar codes, serial numbers and QR codes instead of TTO labels reduces the cost of high-volume production. What’s more, whether using a 3D galvanometer or adding additional control axes, it’s easier than a cutter to mark complex-looking products or integrate them into automated production lines. Examples include storage containers, furniture and decorative items, and popsicle sticks.

Both laser marking and cutting machines can be used for deep engraving or cutting of wood and bamboo products. Cutting machines allow for faster engraving and cutting, but often require pre-treatment such as degreasing, cleaning and sanding to ensure results, and often require enclosed cabinets for exhaust, which is not conducive to integrating conveyors. We typically use marking machines for more accurate engraving without the need for pre-treatment, making them more suitable for automated use.

The first laser cleaning applications in the 1970s used CO2 lasers to clean artifacts and buildings. Precise control of the laser beam’s focus and energy to vaporize dirt and paint without damaging valuable woodwork made it the first choice for this type of application. In recent years, the popular fiber laser cleaner has become the ideal tool for cleaning wood and bamboo products due to the poor absorption of the 1064nm wavelength by wood products.

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?