Scribe Marking and Engraving: What You Should Know

Scribe Marking is a precise technique used to leave a permanent mark on a variety of surfaces. It involves using a sharp tool or stylus to etch lines or patterns into a material by applying pressure. This process is generally less invasive than engraving. Let’s take a closer look at the differences between scratching and engraving.

What is Scribe Marking?

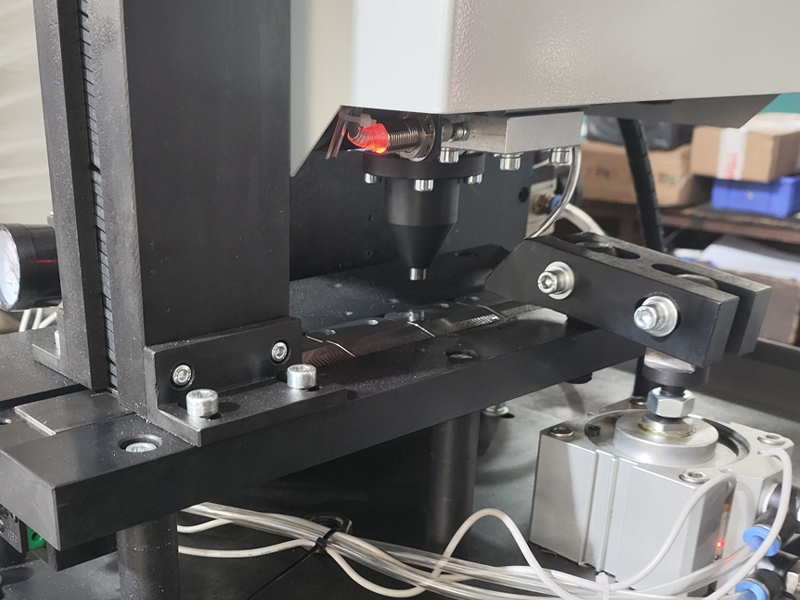

Unlike engraving, which typically removes material from the surface, a scribe marking machine uses a hard stylus or needle to press into the material, creating a visible line or groove. The process is often automated, allowing for high consistency and precision, making it ideal for applications that require fine detail and accurate marks without the need for deeper cuts.

These machines operate in a relatively simple manner. A stylus or marking tool is mounted onto a carriage or gantry that moves along the material’s surface, following the programmed path. This path can be dictated by CAD (computer-aided design) software, which allows for intricate patterns, text, or serial numbers to be marked with exceptional precision. The machine can either work on flat or 3D surfaces, depending on its configuration, and the depth of the mark is typically shallow but clear enough for identification or traceability purposes.

Scribe Marking Machine

There are two main types of scribe marking machines: mechanical scribe marking machines and laser scribe marking machines.

- Mechanical Scribe Marking Machines: These machines utilize a physical stylus or pen-like tool that makes direct contact with the material’s surface, pressing in to leave a mark. The stylus is often crafted from durable materials like tungsten carbide to resist wear and tear. Mechanical scribe marking machines are ideal for marking softer metals and plastics, offering relatively high-speed operation, which makes them well-suited for high-volume production environments.

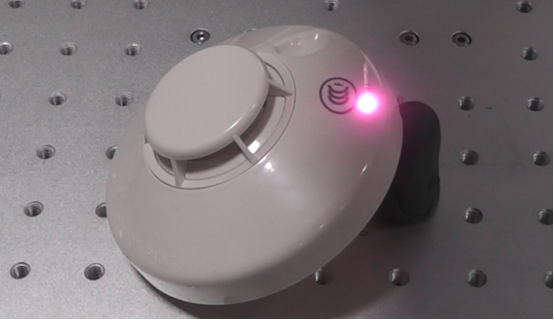

- Laser Scribe Marking Machines: While less common, some scribe marking systems employ laser technology to etch precise lines onto a material. A high-energy laser beam is focused onto the surface, creating a permanent and accurate mark. This method is particularly effective for marking materials that are challenging for traditional mechanical marking tools, such as ceramics, glass, and composites.

Materials for Scribe Marking

Scribe marking is versatile and can be applied to a wide range of materials, though it is particularly effective on softer surfaces. Common materials used for scribe marking include:

- Metals: Lightweight metals like aluminum, brass, and mild steel are ideal for scribe marking due to their relatively soft surface, which allows for precise, shallow marks.

- Plastics: Materials like ABS, PVC, and polycarbonate are commonly marked with scribe tools. The process leaves clear, visible lines without compromising the integrity of the material.

- Ceramics: Scribe marking is often used on ceramics for fine detailing or part identification.

- Composites: Carbon fiber and fiberglass are also suitable for scribe marking, allowing for accurate labeling without damaging the material’s strength.While scribe marking works best on softer materials, it is a flexible technique adaptable to a wide variety of substrates.

While scribe marking works best on softer materials, it is a flexible technique adaptable to a wide variety of substrates.

What is Engraving?

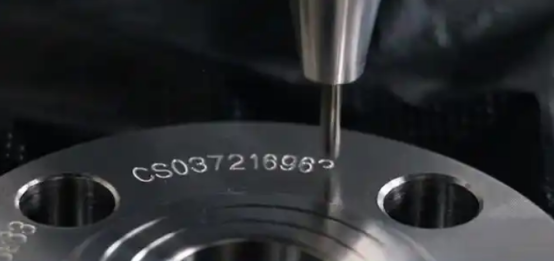

Engraving, on the other hand, is a more intense process where a cutting tool or laser removes material from the surface to create deeper, more permanent marks. Engraving can be used for a variety of applications such as artistic design, branding, and creating identification marks that need to be highly durable and legible over time.

Types of Engraving Machines Machine

Engraving machines are versatile tools for creating permanent, detailed marks by removing material from a surface. They include rotary engravers, laser engravers, and chemical etching systems, each suited to specific needs.

Engraving machines are versatile tools for creating permanent, detailed marks by removing material from a surface. They include rotary engravers, laser engravers, and chemical etching systems, each suited to specific needs.

- Rotary Engraving Machines use a spinning bit to carve into materials like metal, plastic, and wood. Adjustable for depth, they are ideal for industrial use, signage, and jewelry making.

- Laser Engraving Machines employ a focused light beam to vaporize surface material, producing precise, permanent marks. Suitable for metals, wood, glass, and leather, they allow intricate designs with minimal wear on the machine and can create multi-tonal effects.

Chemical Etching Systems use corrosive agents to engrave patterns, commonly in mass production for circuit boards or decorative metal designs. However, this method is less environmentally friendly and versatile compared to rotary and laser systems.

- Rotary Engraving Machines use a spinning bit to carve into materials like metal, plastic, and wood. Adjustable for depth, they are ideal for industrial use, signage, and jewelry making.

- Laser Engraving Machines employ a focused light beam to vaporize surface material, producing precise, permanent marks. Suitable for metals, wood, glass, and leather, they allow intricate designs with minimal wear on the machine and can create multi-tonal effects.

- Chemical Etching Systems use corrosive agents to engrave patterns, commonly in mass production for circuit boards or decorative metal designs. However, this method is less environmentally friendly and versatile compared to rotary and laser systems.

Materials for Engraving

Engraving is a versatile process suitable for a wide range of materials, making it popular across industries and creative applications.

- Metals: Durable materials like stainless steel, aluminum, brass, copper, and precious metals like gold and silver are ideal for engraving. These are often used for industrial parts, jewelry, and personalized gifts.

- Plastics: Engraving is commonly performed on acrylic, ABS, polycarbonate, and other robust plastics, often for creating signage, tags, or decorative designs.

- Wood: Engraving on wood offers a rustic, aesthetic appeal, making it perfect for furniture, plaques, and custom decor.

- Glass: Delicate glass engraving creates elegant designs or branding for drinkware, awards, or artistic pieces.

Other materials like leather, stone, and ceramics can also be engraved, offering unique textures and effects depending on the medium.

Key Differences Between Scribe Marking and Engraving

Although both scribe marking and engraving serve to create permanent markings, they differ in their processes, applications, and material compatibility. Here’s a closer look at their key differences:

| Aspect | Scribe Marking | Engraving |

| Technique | Uses a stylus to etch shallow lines without removing material. | Removes material using a cutting tool or laser. |

| Marking Depth | Creates shallow, precise marks. | Produces deeper, more durable indentations. |

| Material Suitability | Best for softer materials like aluminum, plastics, and thin metals. | Suitable for harder materials such as steel, glass, and wood. |

| Application | Ideal for traceability, part labeling, and serial numbers. | Used for logos, decorative designs, and high-durability markings. |

| Visual Impact | Produces clean, subtle marks that are functional but less prominent. | Creates bold, highly visible marks. |

| Durability | Good for applications requiring precision but less wear resistance. | Excellent for enduring harsh conditions and heavy use. |

| Process Noise | Quieter operation due to a smooth, stylus-based process. | Often louder due to material removal or vaporization. |

When to Choose Scribe Marking or Engraving?

- Scribe Marking: Ideal for precision-focused applications on softer materials, especially when the mark’s visibility is secondary to its functional use, such as traceability.

- Engraving: The best choice for durable, high-impact markings or decorative designs on harder surfaces where longevity and prominence are critical.

Need to Find a Scribe Marking or Engraving Machine Manufacturer?

If you’re considering purchasing a scribe marking or engraving machine manufacturer, there are numerous companies that specialize in high-quality machines tailored to your specific needs. Some key factors to consider include:

- Machine Type: Determine whether you need a manual, automated, or laser-based system.

- Material Compatibility: Make sure the machine can handle the materials you’re working with.

- Precision and Speed: Depending on your application, ensure the manufacturer offers machines with the required level of precision and efficiency.

- Support and Maintenance: Look for manufacturers that provide strong customer support and maintenance services.

Zixu is a leading provider of marking machines that specializes in both scribe marking and engraving technologies. Zixu is known for its high-quality, reliable machines that are designed to meet the diverse needs of industries ranging from automotive to electronics, aerospace, and more. Whether you need a machine for small batch production or high-volume applications, we offers a range of solutions that can help improve efficiency and accuracy in your operations.

Recommended Products