The Benefits and Applications of Metal Tag Engraving Machines

Metal tag engraving machines offer a reliable and efficient solution for creating durable, customized, and traceable markings on metal components. These machines empower businesses to enhance product identification, asset management, and brand recognition. In this article, we delve into the numerous benefits and applications of metal tag engraving machines, exploring the two most common types: desktop dot peen engravers and scribe engravers. We will also provide insights on how to choose the right machine to meet your specific needs.

Why Choose a Metal Tag Engraving Machine?

- Permanent and Durable Markings: Metal tag engraving machines create deep, precise markings that are highly resistant to wear, corrosion, and fading. This ensures that the engraved information remains legible for a long time, even in harsh environments.

- Customization: These machines offer a high degree of customization, allowing you to create unique designs, logos, and text. You can easily adjust the font size, style, and layout to meet your specific requirements.

- Versatility: Metal tag engraving machines can handle a wide range of materials, including stainless steel, aluminum, brass, and more. They can also engrave various shapes and sizes of tags.

- Efficiency: Modern engraving machines are highly efficient and can produce large quantities of engraved tags quickly. This can significantly reduce production time and costs.

- Accuracy: The precision of these machines ensures that each engraved tag is consistent and accurate, minimizing errors and waste.

- Traceability: Engraved tags can be used to track products, parts, and assets throughout their lifecycle, improving inventory management and reducing the risk of loss or theft.

- Compliance: Many industries have strict regulations regarding product identification and traceability. Metal tag engraving machines can help businesses meet these compliance requirements.

- Branding: Engraved tags can be used to enhance your brand image by adding a professional and customized touch to your products.

Applications of Metal Tag Engraving Machines

- Industrial Identification: Marking equipment, tools, components, and parts with unique identification numbers, barcodes, or QR codes for inventory management, asset tracking, and quality control.

- Automotive Industry: Engraving VIN numbers, part numbers, and other essential information onto automotive components, such as engines, transmissions, and chassis.

- Medical Devices: Marking medical implants, surgical instruments, and equipment with patient identification, sterilization dates, and lot numbers.

- Aerospace: Engraving identification markers on aircraft parts, components, and tools for traceability and maintenance purposes.

- Electronics Manufacturing: Marking circuit boards, electronic components, and enclosures with product information, serial numbers, and date codes.

- Jewelry and Gifts: Creating personalized jewelry, gifts, and awards with custom engravings.

- Tool and Die Making: Engraving tooling with part numbers, customer names, and other relevant information.

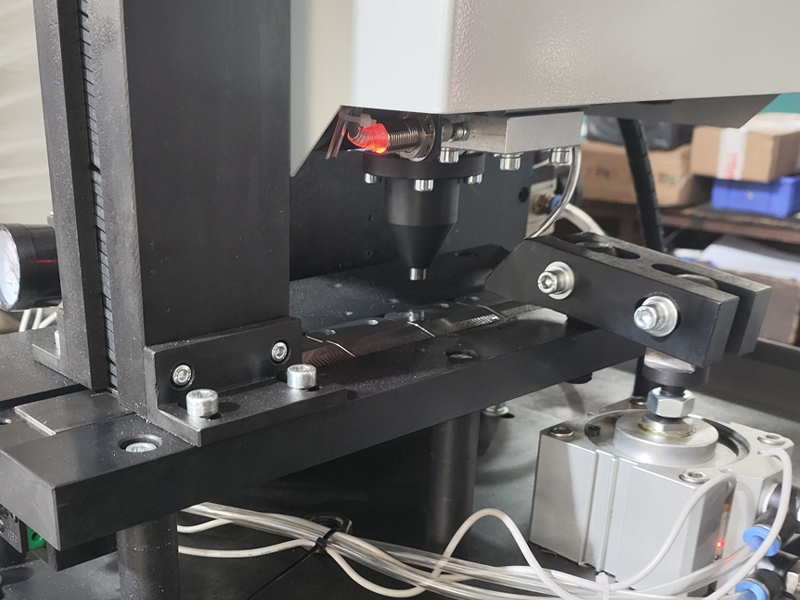

Two Common Types of Metal Tag Engraving Machine

| Feature | Desktop Dot Peen Engraver | Scribe Engraver |

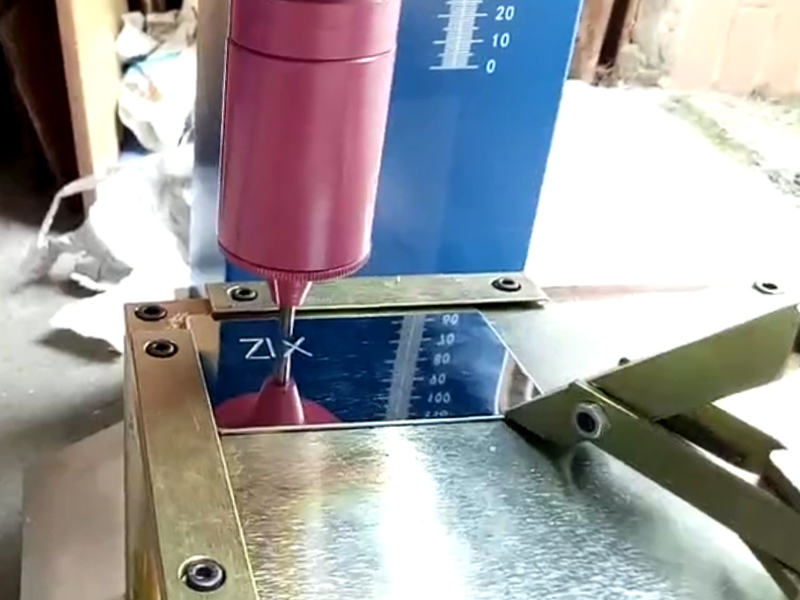

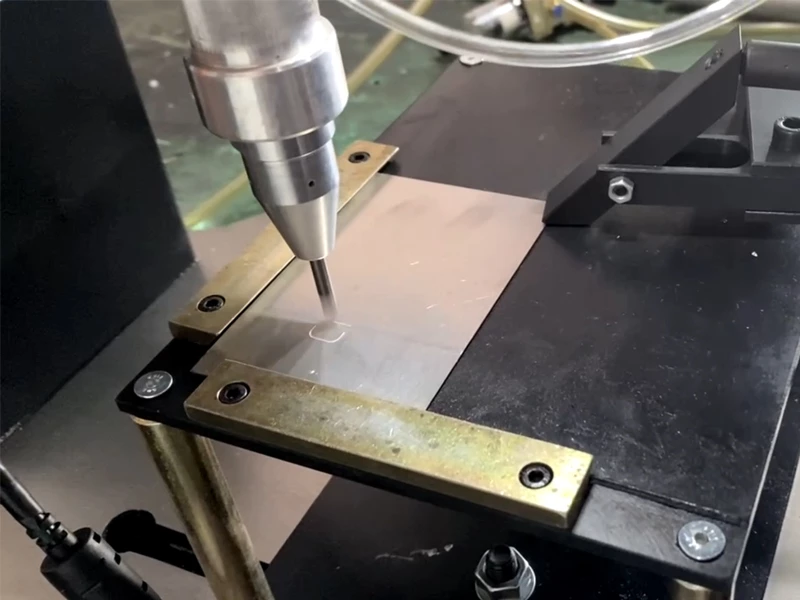

| Marking Method | Uses a pin to strike the metal surface, creating small dots that form characters or patterns. | Uses a cutting tool to scribe lines into the metal surface, forming characters or patterns. |

| Materials | Suitable for a wide range of metals, including stainless steel, aluminum, brass, titanium, etc. | Best suited for softer metals like aluminum and copper. |

| Markings | Produces deep, permanent markings that are resistant to wear and corrosion. | Creates clear and legible markings, but may be less durable than dot peen markings on harder metals. |

| Speed | Relatively fast marking speed. | Slower marking speed compared to dot peen engravers. |

| Noise Level | Can be relatively noisy due to the impact of the pin. | Generally quieter than dot peen engravers. |

| Applications | Ideal for industrial applications where durability and permanence are essential, such as marking equipment, components, and parts. | Well-suited for applications requiring clear and legible markings on softer metals, such as jewelry and decorative items. |

| Advantages | Durable markings, versatile, relatively fast, affordable. | Clear markings, quieter operation. |

Summary

- Desktop dot peen engravers are excellent for creating deep, permanent markings on a wide range of metals. They are durable, versatile, and relatively affordable. However, they can be noisy and may not produce the same level of detail as laser engraving.

- Scribe engravers are ideal for creating clear and legible markings on softer metals. They are quieter and can produce fine details, but they are generally slower and more expensive than dot peen engravers.

Choosing the Right Machine

The best choice for you will depend on your specific needs and budget. Consider the following factors:

- Materials: What types of metals will you be engraving?

- Markings: What type of markings do you need (e.g., deep and durable, or clear and legible)?

- Speed: How quickly do you need to produce engravings?

- Budget: What is your budget for the engraving machine?

By carefully considering these factors, you can select the most suitable metal tag engraving machine for your application.

Metal Tag Engraving Machines Improve Your Operations

Metal tag engraving machines have transformed how companies identify, track, and brand their products. These machines provide numerous advantages by producing long-lasting, customizable, and traceable markings. Whether you work in manufacturing, automotive, medical, or another industry, investing in a metal tag engraving machine can significantly improve your operations. When selecting a machine, consider the types of metals you’ll be engraving, the desired markings, speed requirements, and budget constraints. If you have any questions, contact professional metal tag engraving machine supplier Zixu.

Recommended Products