Top Benefits of Using Pneumatic Dot Peen Marking Machine for Metal Parts

Marking metal parts with permanent and precise identification marks is crucial for various industrial applications. One technology that has become a favorite in the manufacturing industry is the pneumatic dot peen marking machine. With its capability to engrave everything from serial numbers to barcodes on various surfaces, this machine has established itself as a reliable and efficient marking solution.

So, can it also be used for metal parts?

Can Pneumatic Dot Peen Marking Machine be Used for Metal Parts?

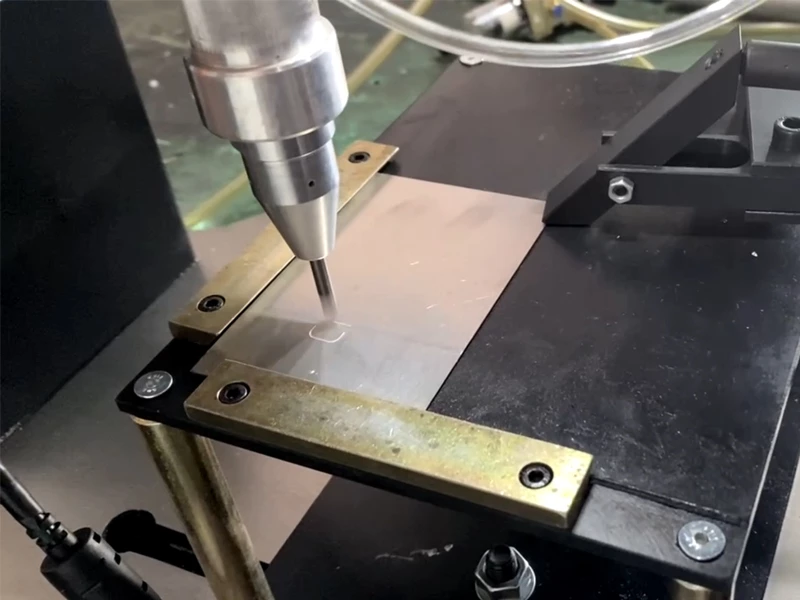

Yes, pneumatic dot peen marking machines are highly effective for marking metal parts, making them a go-to solution in industries where durability and traceability are critical. These machines utilize a pneumatically driven stylus to create a series of precise indentations, or “dots,” on the surface of a material, forming text, logos, serial numbers, or 2D codes. The technology is particularly well-suited for metals because of its ability to generate deep and permanent marks that remain legible over time, even in harsh conditions like high temperatures, chemical exposure, and physical wear.

- One of the key advantages of pneumatic dot peen marking for metal is that it can mark a wide range of metal types, from softer materials like aluminum and brass to harder alloys such as stainless steel and titanium. The machine’s marking depth and pressure can be adjusted to suit the hardness of the metal, ensuring optimal results without damaging the part’s structural integrity.

- Furthermore, the machine is highly efficient in terms of energy use and operational costs. It requires only compressed air for the marking process, eliminating the need for consumables like inks or engraving tools. This not only reduces costs but also enhances the sustainability of the marking process.

Overall, pneumatic dot peen machines are an ideal solution for marking metal parts with high precision, durability, and efficiency.

Top Benefits of Using Pneumatic Dot Peen Marking Machine

Pneumatic dot peen marking machines offer significant advantages for industries that need permanent and reliable markings on metal parts. Let’s explore the four most important benefits in more detail:

Durable and Permanent Marking

One of the primary reasons for choosing a pneumatic dot peen marking machine is the durability and permanence of the marks it produces. This marking method creates deep indentations on the surface of metal parts using a pneumatically driven stylus, which is particularly effective on materials like steel, aluminum, and other alloys. These markings are not superficial; they can withstand extreme environmental conditions such as:

- High temperatures: Ideal for industries like aerospace or automotive, where components are often exposed to heat.

- Corrosive environments: Marks remain intact in harsh environments, such as in the oil and gas sector or chemical manufacturing, where components are exposed to chemicals or corrosive materials.

- Mechanical wear: The marks do not fade or wear off even with repeated handling or exposure to friction, making them suitable for industrial tools and heavy machinery parts.

This durability ensures that information such as serial numbers, part numbers, and 2D data codes remain legible throughout the entire lifecycle of the part, contributing to enhanced traceability and regulatory compliance.

Cost-Effective Operation and Maintenance

Pneumatic dot peen marking systems offer a highly cost-effective alternative to other marking technologies. They require fewer consumables and have lower long-term operational costs. Unlike laser marking, which involves a higher initial investment and ongoing maintenance, or ink-based systems that require frequent ink replenishment, dot peen machines rely solely on compressed air. The following factors contribute to their cost-effectiveness:

- No consumables: After installation, the machine only needs compressed air to operate, eliminating the need for expensive inks, chemicals, or regularly replaced engraving tools.

- Low maintenance: Built to be mechanically durable, these machines have fewer components that wear out or need frequent servicing, leading to minimal downtime and reduced maintenance costs.

- Energy efficiency: Pneumatic systems consume significantly less energy compared to more power-hungry technologies like lasers, making them ideal for businesses focused on optimizing operational costs.

Overall, pneumatic dot peen systems enable companies to reduce long-term expenses while delivering durable, high-quality markings.

Efficient for High-Speed, High-Volume Production

Efficiency is a critical factor in modern manufacturing, especially in industries like automotive, electronics, or consumer goods, where high-volume production is essential. Pneumatic dot peen marking machines excel in these environments due to their ability to produce marks quickly and accurately, without sacrificing quality. Here’s how this efficiency benefits high-speed manufacturing:

- Fast marking process: The pneumatic stylus operates at high speeds, producing thousands of small dots in quick succession to create readable and precise engravings. This rapid operation is ideal for production lines where speed is crucial.

- Minimal impact on cycle times: The machine’s marking speed ensures that it does not slow down the overall production process, allowing manufacturers to integrate it into assembly lines without affecting productivity.

- Automated operation: Pneumatic dot peen machines can be easily integrated with automated systems, including robotic arms, conveyors, and programmable logic controllers (PLCs). This enables seamless operation in smart manufacturing environments where minimal human intervention is required, further increasing throughput.

In high-demand industries, the combination of speed, accuracy, and automation capabilities ensures that pneumatic dot peen marking machines keep up with production requirements while maintaining consistent marking quality.

High Versatility for Different Marking Requirements

Pneumatic dot peen machines stand out for their remarkable versatility in meeting diverse marking needs. These machines can handle a range of marking tasks, from logos and alphanumeric characters to barcodes and complex 2D Data Matrix codes. This adaptability brings several significant benefits:

- Wide range of markings: Dot peen machines are capable of producing various types of marks, including deep engravings, fine text, and intricate designs on different metal components, all without the need for multiple machines or complicated setups.

- Multi-material compatibility: These machines can mark not only metals like aluminum, stainless steel, and hardened alloys but also softer materials such as plastic or wood, offering cross-material flexibility.

- Customizable depth and size: The marking depth and pressure can be easily adjusted to suit the specific material or application, allowing for shallow marks on soft metals or deeper engravings on harder surfaces.

This versatility makes pneumatic dot peen systems well-suited for a broad range of industrial applications, from delicate electronics components to heavy-duty parts used in aerospace and automotive industries.

Whether you’re looking to mark metal parts in a high-volume production line or need a flexible marking system for various materials, pneumatic dot peen technology offers an ideal solution. Its ability to produce permanent, high-quality marks without the ongoing costs of consumables makes it an invaluable asset in sectors like automotive, aerospace, and manufacturing.

Industrial Application of Pneumatic Dot Peen Marking Machine for Metal Parts

Pneumatic dot peen marking machines are widely used in industrial settings for marking metal parts with permanent, traceable marks. Here are some key industrial applications of pneumatic dot peen marking machines for metal parts:

| Industry | Application | Examples of Metal Parts Marked |

| Automotive | VIN marking, part identification, engine component tracking | Chassis, engine blocks, brake pads, gears, bearings |

| Aerospace | Component traceability, compliance with standards, Data Matrix coding | Turbine blades, landing gear, structural components |

| Metal Fabrication | Batch and lot number marking, tool and die marking, inventory management | Metal sheets, beams, tools, molds, dies |

| Oil and Gas | Pipe and valve marking, pressure vessel identification | Metal pipes, valves, fittings, pressure vessels |

| Defense & Military | Weapon part marking, military equipment identification | Firearms, ammunition components, vehicle parts |

| Electronics | Marking metal casings, terminal identification | Electronic device casings, electrical connectors, bus bars |

| Medical Devices | Surgical instrument marking, implant traceability | Surgical tools, orthopedic implants |

| Heavy Machinery | Part serial number marking, equipment identification | Excavator parts, bulldozer components, crane parts |

| Metalworking & Machining | Tool identification, mold marking | Cutting tools, drill bits, machine parts, molds |

This table captures the major industries, applications, and specific metal parts involved in the use of pneumatic dot peen marking machines.

How to Choose A Reliable Pneumatic Dot peen Marker Supplier

When selecting a supplier for pneumatic dot peen markers, it’s important to consider factors such as industry experience, product range, and after-sales support.

Zixu stands out as a leading supplier, offering high-quality, customizable marking solutions tailored to various industrial needs. With years of experience in the field, we provide durable and efficient machines that can handle different marking requirements. Our comprehensive technical support ensures smooth installation and long-term reliability.

Known for Our innovative approach, Zixu delivers top-tier solutions for industries ranging from automotive to aerospace, making them a trusted partner for marking technologies.

If you have any need, please feel free to contact us.

Recommended Products