UV Laser Marking Machines: A Precision Tool for Glass Engraving

Glass, a versatile material with endless applications, often requires precise and durable markings. Traditional methods, such as etching or sandblasting, can be time-consuming and may not always produce the desired results. However, the advent of UV laser marking technology has revolutionized the glass engraving industry. This innovative technique offers unparalleled precision, versatility, and efficiency, making it the preferred choice for a wide range of applications.

Zixu will get you into the science behind UV laser marking, exploring the key components and processes involved. We will discuss the various types of marks that can be created on glass using this technology, as well as the numerous advantages it as a glass laser marking machine offers over traditional methods. By understanding the intricacies of UV laser marking, we can appreciate its potential to transform the way we personalize and enhance glass products.

The Science Behind UV Laser Marking

Ultraviolet Light Source

At the core of a UV laser marking machine lies a powerful ultraviolet laser source. This sophisticated device emits a highly concentrated beam of light within the ultraviolet spectrum. The specific wavelength of this light is carefully selected to interact with the glass material and induce the desired marking effect.

High-Precision Optics

The generated UV laser beam is meticulously guided through a series of high-precision lenses and mirrors. This optical system serves to focus the beam onto an incredibly small spot on the glass surface. The diameter of this focused beam can be as minuscule as a few micrometers, enabling the creation of extremely fine and detailed markings.

Photochemical Reaction

When the intense, focused UV laser beam impinges upon the glass surface, it initiates a photochemical reaction. This reaction involves the absorption of energy from the laser beam by the glass material, leading to a localized alteration in the glass’s physical and chemical properties.

Material Removal or Color Change

The outcome of the photochemical reaction can vary depending on the specific laser settings and the type of glass being marked. Two primary effects can occur:

- Material Removal: In this case, the intense energy of the laser beam vaporizes a minuscule amount of glass material, effectively removing it from the surface. This process creates a permanent mark in the form of an etched or engraved pattern.

- Color Change: Alternatively, the laser beam can induce a localized color change in the glass. This occurs as the laser alters the chemical structure of the glass surface, leading to a modification in its optical properties. This technique is particularly useful for creating intricate designs and patterns with varying shades and hues.

What Types of Marks Can Be Created on Glass Using a UV Laser?

UV laser marking machines have revolutionized the way we mark and personalize glass surfaces. These advanced machines offer a wide range of possibilities for creating diverse and intricate markings. Here are some of the most common types of marks that can be produced:

- Text: Clear and legible text can be engraved onto glass surfaces in a variety of fonts, sizes, and styles. This is ideal for product labeling, part identification, or decorative purposes. Whether it’s a simple product name or a complex set of instructions, UV laser marking can deliver precise and durable text.

- Logos: Detailed logos and branding elements can be precisely etched onto glass surfaces, enhancing product recognition and brand visibility. From small, discreet logos to large, eye-catching designs, UV laser marking can reproduce logos with remarkable accuracy.

- Barcodes and QR Codes: Machine-readable barcodes and QR codes can be incorporated into glass products for efficient inventory management, tracking, and authentication. These codes can be easily scanned and decoded, providing valuable information about the product’s origin, manufacturing date, and other relevant details.

- Serial Numbers: Unique serial numbers can be laser-marked onto glass components to facilitate traceability and quality control. These numbers can help identify individual products, track their production history, and ensure compliance with industry standards.

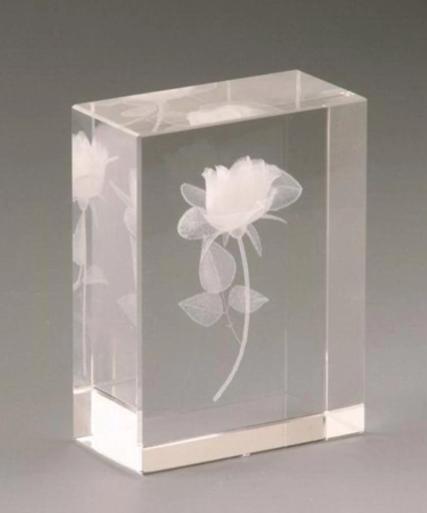

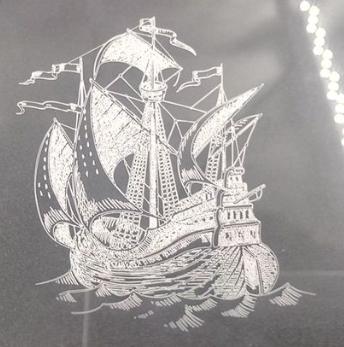

- Decorative Patterns: Intricate designs, patterns, and artwork can be engraved onto glass surfaces, adding aesthetic appeal and value to the product. From simple geometric shapes to complex, artistic designs, UV laser marking can bring creative visions to life on glass.

What Are the Advantages of Using a UV Laser Marking Machine for Glass?

UV laser marking machines have revolutionized the way we mark and personalize glass surfaces. These advanced machines offer a multitude of benefits that make them an indispensable tool for various industries. Here are some key advantages:

- Exceptional Precision: UV lasers provide unparalleled precision and accuracy, enabling the creation of intricate details, fine lines, and small text. This level of detail is crucial for applications like jewelry, medical devices, and high-end electronics, where precision is paramount.

- Long-Lasting Marks: The marks produced by UV laser marking are highly durable and resistant to fading, scratching, and chemical corrosion. This ensures that the markings remain clear and legible for years to come, even in harsh environments such as outdoor signage or industrial settings.

- Versatility: UV laser marking machines can be used to mark a wide range of glass types, including tempered glass, laminated glass, and specialty glasses. This versatility makes them suitable for various industries, from automotive to electronics, where different types of glass are used for diverse applications.

- Non-Contact Process: The non-contact nature of UV laser marking eliminates the risk of physical damage to the glass surface. This is particularly important for delicate or fragile glass components, such as optical lenses or museum artifacts.

- Environmental Friendliness: UV laser marking is an eco-friendly process that does not involve harmful chemicals or waste. This makes it a sustainable choice for manufacturers and consumers alike, reducing the environmental impact of the marking process.

Recap

UV laser marking machines have emerged as a powerful and versatile tool for glass engraving. By harnessing the power of ultraviolet light and precision optics, these machines can create a wide range of markings, from simple text to intricate designs. The non-contact nature of the process ensures that the glass surface remains pristine, while the durability of the markings withstands the test of time.

As technology continues to advance, you can expect even greater innovations in UV laser marking with laser marking machine supplier Zixu.

Recommended Products