VIN Etching Machine vs. VIN Punching Machine: Which is Better for Your Vehicle?

Vehicle Identification Numbers (VINs) are crucial for identifying and securing vehicles. They serve as a unique fingerprint, distinguishing one car from another. Protecting this number from tampering or theft is vital for vehicle owners. Two commonly used methods for marking VINs on vehicles are VIN etching and VIN punching. But which method is better for your vehicle? Let’s explore the pros and cons of each.

Main Types of Technologies for VIN Marking

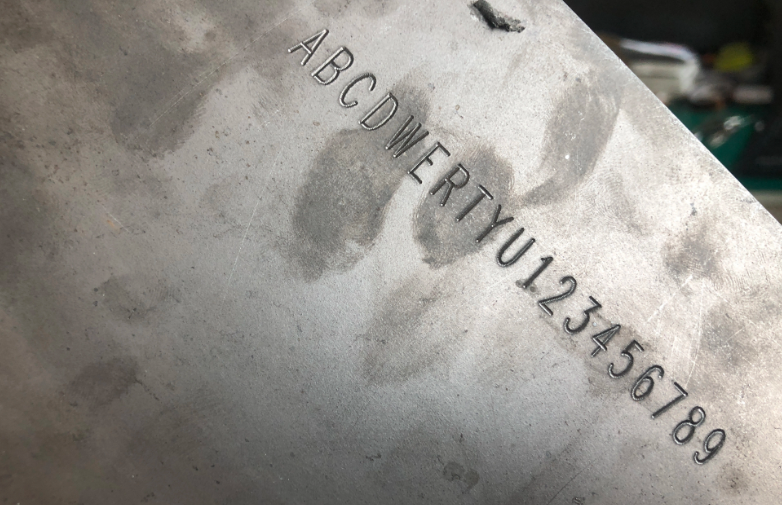

- Chemical Etching: This method involves using a stencil and an acid-based solution to engrave the VIN onto the surface. The chemical reaction ensures a precise, permanent mark, making it effective for long-lasting identification.

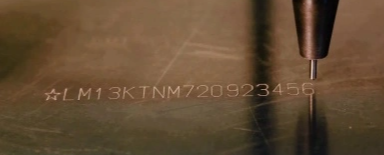

- Laser Etching: Laser etching uses a high-precision laser beam to vaporize a thin layer of the material, creating the VIN. Known for its speed, accuracy, and clean finish, laser etching is widely used in automotive and manufacturing industries.

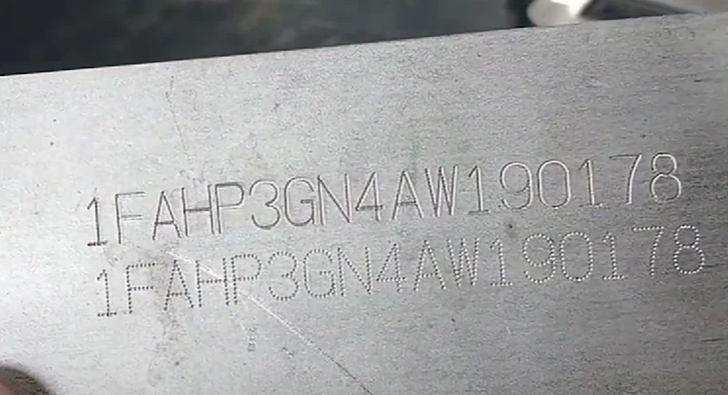

- Mechanical Punching: In this process, a physical punch is used to stamp the VIN directly onto the material. The method results in a clear, deep impression and is commonly employed for heavy-duty applications, such as in commercial vehicles and machinery.

- Dot Peen Marking: This method employs a small, vibrating pin to create a series of tiny dots that form the VIN on the surface. It’s a fast technique suitable for various materials, providing durable, clear markings that resist wear.

- Inkjet Printing: Inkjet printing uses ink droplets to apply the VIN to the surface. Although less permanent than etching or punching, it is commonly used for temporary identification or tagging purposes during manufacturing.

Each of these methods caters to specific needs, depending on factors such as durability, precision, cost, and material compatibility.

What is VIN Etching Machines?

A VIN etching machine is a tool used to permanently engrave a vehicle’s unique Vehicle Identification Number (VIN) onto surfaces, typically glass or metal. This process enhances security by making the vehicle or its parts easily identifiable, which can deter theft. There are two primary types of VIN etching methods:

- Chemical Etching: This technique involves the use of a stencil and an acid-based solution to etch the VIN onto a surface. Through a controlled chemical reaction, it produces a sharp, durable, and permanent mark.

- Laser Etching: This process utilizes a high-precision laser beam to vaporize a thin layer of the material, forming the VIN. It is known for its speed, cleanliness, and exceptional accuracy.

Key Advantages of VIN Etching:

- Non-Invasive: The process does not alter the vehicle’s structural integrity.

- Visible Deterrent: VINs etched on windows or glass are highly visible, discouraging thieves who would find it harder to resell marked parts.

- Fast and Efficient: Etching is a straightforward process with minimal waste or cleanup.

VIN etching is particularly popular for marking windshields and other glass surfaces, making it a simple yet effective method to enhance vehicle security.

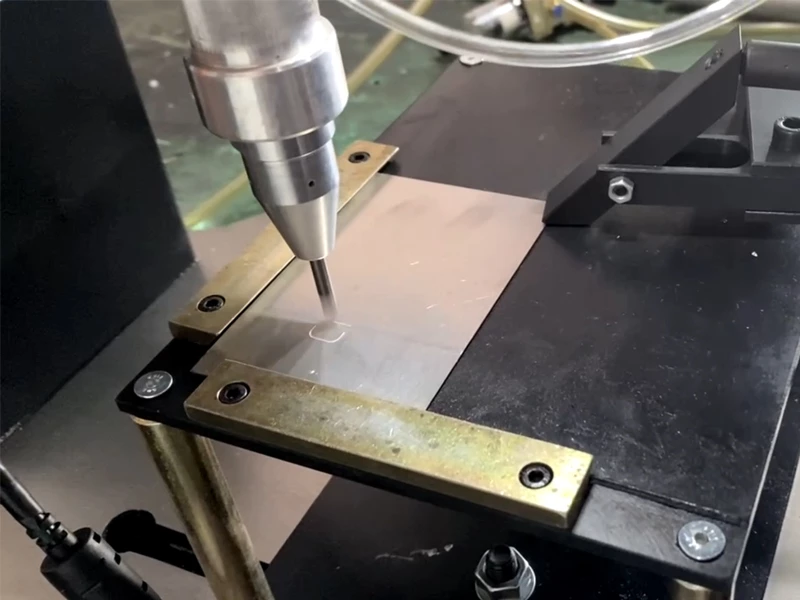

What is VIN Punching Machines?

A VIN punching machine is a mechanical device designed to permanently stamp or emboss a Vehicle Identification Number (VIN) onto metal surfaces. The machine uses a hardened steel punch and significant force to create deep, durable impressions in materials like the vehicle’s chassis, engine block, or other structural components.

How It Works:

A die or punch containing the desired VIN characters is aligned with the target surface.

Using hydraulic, pneumatic, or manual force, the punch is pressed into the metal, embedding the characters.

Key Advantages:

- Durability: The punched VIN is exceptionally resistant to wear, making it perfect for components subjected to tough environments, like undercarriages or engine blocks.

- Tamper-Resistance: The deep, permanent markings of a punched VIN make it nearly impossible to alter or remove, significantly boosting security.

- Compliance: Punching is frequently required by regulatory bodies to ensure the traceability of vehicles throughout their lifespan.

- Applications: VIN punching machines are commonly used in manufacturing plants, repair shops, and service centers to comply with legal and safety standards for heavy-duty vehicles and equipment.

VIN Etching Machine vs. VIN Punching Machine

To help you better understand the differences between VIN etching machines and VIN punching machines, here’s a clear comparison summarized in the table below:

| Feature | VIN Etching Machine | VIN Punching Machine |

| Method | Uses chemicals or laser technology to engrave the VIN. | Uses mechanical force to stamp or punch the VIN. |

| Surface | Primarily for glass surfaces (windshields, windows). | Mainly for metal surfaces (vehicle frame, engine parts). |

| Durability | Resistant to wear, but mainly for visible markings. | Very durable, deeply embedded, resistant to harsh conditions. |

| Purpose | Prevents theft by marking windows or other visible areas. | Ensures permanent, regulatory-compliant VIN marking. |

| Cost | Typically lower; cost-effective for personal use. | Higher cost; more suitable for industrial settings. |

| Flexibility | Portable, suitable for smaller or individual use. | Stationary, requires heavy machinery and setup. |

| Portability | Highly portable and easy to use anywhere. | Typically not portable; used in workshops or factories. |

| Environmental Impact | Cleaner process, especially with laser technology. | May create metal waste and requires more energy. |

This comparison should help clarify which machine might be better suited to your needs, depending on whether you’re looking for a solution to prevent theft or to comply with manufacturing standards.

Considerations When Choose

- Purpose and Use Case

The primary reason for choosing a VIN marking method depends on your purpose. If the goal is to deter theft and enhance the visibility of your VIN for identification purposes, a VIN etching machine is ideal. It’s commonly used to mark windows or glass surfaces, making it more noticeable to potential thieves. In contrast, VIN punching is ideal for regulatory and manufacturing purposes where the VIN must be permanently marked on the vehicle’s chassis or other metal parts, offering a tamper-resistant solution that is more difficult to modify.

- Durability Requirements

For long-lasting, robust durability, VIN punching is the optimal choice. It creates a deep, permanent mark that remains intact even in extreme conditions, such as corrosion or physical damage. In contrast, while VIN etching is sufficiently durable for most everyday applications, it may not offer the same level of resilience over time, especially for components exposed to harsh environments.

- Surface Material

The type of surface you need to mark will heavily influence your decision. VIN etching works best on glass and soft metals, as it uses a laser or chemical process to etch a permanent mark. VIN punching, however, is designed for harder surfaces like steel or aluminum, as it physically stamps the VIN into the metal, making it much more durable and resistant to wear.

- Cost and Accessibility

VIN etching machines tend to be more affordable and easier to use, making them accessible for individual vehicle owners or small businesses. They are portable and do not require heavy machinery. In contrast, VIN punching machines are generally more expensive and require larger setups, making them more suitable for commercial or industrial use. The higher initial investment might be a consideration if you’re marking multiple vehicles in a workshop or factory setting.

To Sum Up

Choosing between a VIN etching machine and a VIN punching machine ultimately depends on your specific needs. For vehicle owners focused on theft prevention and aesthetics, VIN etching is a practical and affordable choice. For manufacturers and heavy-duty applications, VIN punching offers unmatched durability and compliance.

Evaluate your requirements, surface materials, and budget to make the best decision for your vehicle’s security and traceability. Need any suggestions for your VIN marking project? Contact Zixu Now!

Recommended Products