Vin Number Marking Machine: Portable vs. Benchtop Type

Vin number marking machines are essential tools for engraving Vehicle Identification Numbers (VINs) onto vehicles and parts to meet legal standards, prevent fraud, and aid vehicle tracking. There are two primary types available when it comes to choosing the types – portable Vin number marking machine and benchtop vin marking machine; in this article we explore their features, differences, applications, and selection criteria so that you can make an informed decision when making this important investment.

Portable VIN Number Marking Machines

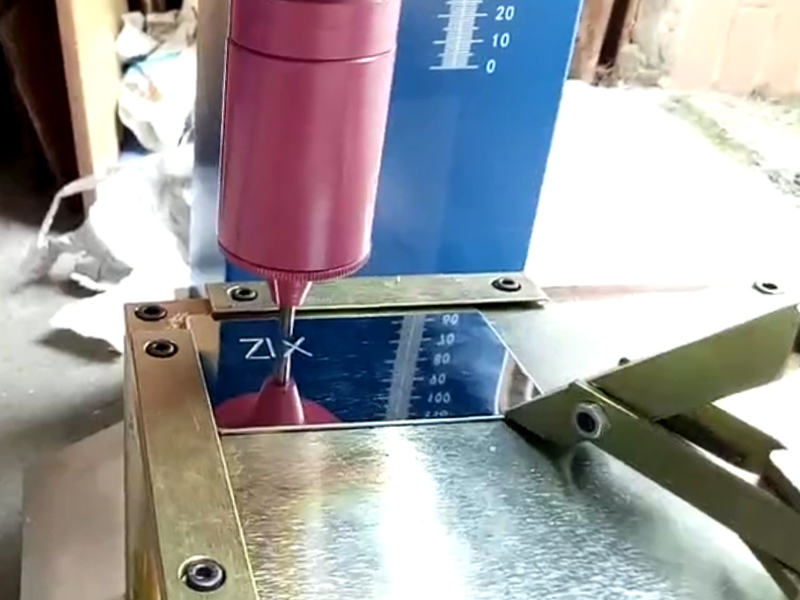

Portable VIN number marking machines are built for flexibility and convenience, making them an excellent choice for professionals working across various locations. Their compact size and lightweight build make these portable marking machines the ideal companions to vehicle inspections, roadside assistance or fieldwork applications – their mobility allows users to transport them easily between sites so that VIN marking tasks can be accomplished efficiently wherever needed.

One of the key advantages of portable VIN marking machines is their ease of use. Designed for quick setup and operation with minimal training needed, these portable marking machines make quick work of VIN marking in dynamic environments such as hospitals. Plus, their rugged construction ensures durability even under adverse weather conditions or challenging settings. Ideal For:

- Law enforcement or regulatory agencies.

- Mobile repair services or roadside assistance teams.

- Situations that require on-site VIN verification or marking in remote areas.

Portable VIN marking machines offer professionals who require flexibility and reliability in their operations a reliable option for VIN marking.

Benchtop VIN Number Marking Machines

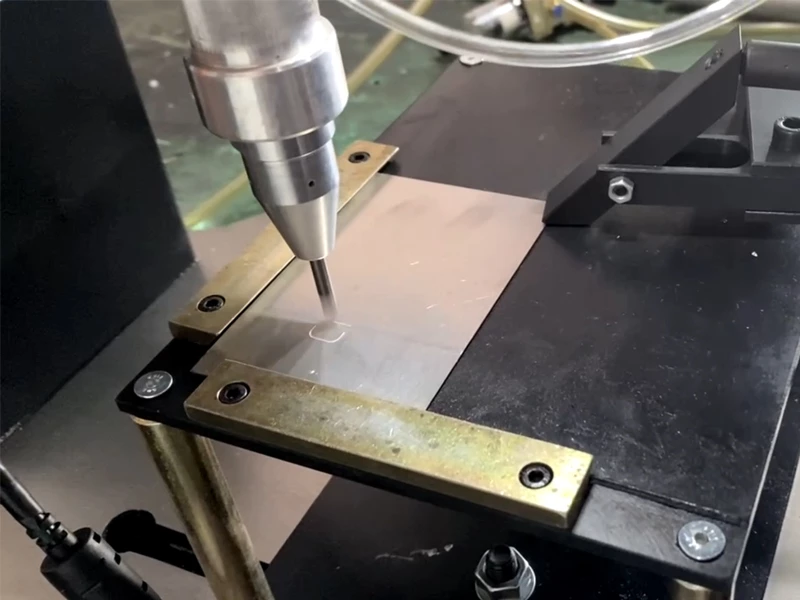

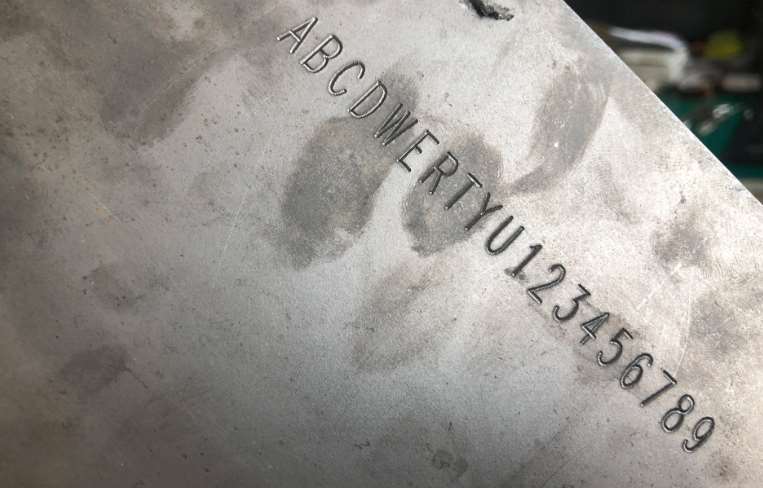

Benchtop VIN number marking machines are engineered for maximum precision, accuracy, and efficiency in industrial and manufacturing settings. Unlike portable models, these fixed machines provide a reliable solution for repetitive marking tasks at high volumes – such as automotive production lines, metal fabrication plants, and industrial workshops where accuracy and consistency are key elements.

Benchtop VIN marking machines stand out due to their sturdy and stable structure, which ensures precise and uniform engraving. Many models also come equipped with powerful marking heads capable of deep, permanent etching on materials like steel, aluminum, and other metals. Many models also provide automated or programmable functions to reduce manual operation while increasing overall efficiency; additionally, these machines are often compatible with factory automation systems for seamless integration into production workflows.

Benchtop VIN marking machines boast many advantages over standard marking methods, including superior engraving accuracy, durability, and capacity to handle mass production. As a result, these marking machines make for ideal choices in businesses that demand consistent and high-quality markings, such as manufacturers or industrial operators prioritizing efficiency and long-term reliability in their marking processes.

Key Differences Between Benchtop and Portable VIN Marking Machines

When deciding between a benchtop and portable VIN marking machine, understanding their key differences is crucial. Here’s a detailed comparison to help you choose the right option for your needs:

| Feature | Portable VIN Marking Machine | Benchtop VIN Marking Machine |

| Mobility | Designed for easy transport and on-site use. | Stationary, meant for fixed locations. |

| Precision | Suitable for basic marking tasks. | Offers high precision for detailed engravings. |

| Power Source | Typically battery-powered or lightweight. | Runs on mains electricity for consistent power. |

| Durability | Built to withstand outdoor and rugged conditions. | Designed for controlled indoor environments. |

| Volume Capacity | Best for low to medium volume tasks. | Ideal for high-volume, repetitive marking. |

| Setup Time | Quick and easy to set up. | Requires initial setup but offers stability. |

| Cost | Generally more affordable. | Higher initial investment but cost-effective for high-volume use. |

This comparison highlights the core differences, which can help you determine which type aligns best with your operational needs.

Applications: Benchtop vs. Portable Vin Number Marking Machine

Selecting either a benchtop or portable VIN marking machine depends heavily on its intended environment and task(s). Each type excels in certain instances; understanding their applications will help make an informed decision.

Portable VIN Marking Machines Applications

Portable VIN marking machines are built for convenience and mobility, making them ideal for marking on-site or in the field.

- Field Services and Inspections: Field services and inspection machines are widely utilized by law enforcement agencies, vehicle inspection teams, and insurance adjusters who need to mark vehicles or parts remotely. Their portability enables quick and effective marking without needing to transport items back to a fixed workstation.

- Automotive Repair and Salvage Yards: Portable machines are ideal for marking vehicles or components that are difficult to move in repair shops and salvage yards, as well as marking salvaged parts for sale or recycling.

- Construction and Heavy Equipment: Portable VIN marking machines are widely utilized at construction sites or industries where heavy machinery needs to be marked directly at the job site.

Portable machines offer businesses that require mobility in different environments a practical solution for working quickly and efficiently.

Benchtop VIN Marking Machines Applications

These marking machines are specifically designed for precision and high-volume production environments where marking takes place at a fixed, controlled location.

- Manufacturing and Assembly Lines: Benchtop marking machines can help automotive or manufacturing plants achieve consistent accuracy when marking large volumes of parts or vehicles with consistent marking accuracy, providing seamless operation for production lines.

- Aerospace and Metalworking Industries: Both these industries require accurate marking on critical components. Benchtop machines provide the stability and power necessary to engrave durable marks on materials like metal that will last long after first application.

- Workshops and Factories: Benchtop machines provide businesses that handle heavy or bulky items with a stable platform for marking. Furthermore, these devices can help companies requiring extensive, repetitive marking over extended periods.

Benchtop machines are an excellent solution for businesses that prioritize precision, efficiency, and the ability to manage large-scale marking tasks.

How to Choose the Suitable One?

Before choosing between portable or benchtop VIN number marking machines, it’s essential to assess your specific operational needs.

If your work involves marking vehicles or parts at multiple locations or on-site, portable machines may be best due to their mobility and ease of use – plus their lightweight nature makes them suitable for field work and field services such as automotive repair shops, salvage yards or law enforcement agencies.

Benchtop machines may be better suited if your operations require high volumes and precise marking. These stationary devices feature stability, precision, and durability – ideal for manufacturing facilities, assembly lines, aerospace industries, or metalworking businesses. In terms of budget and space considerations portable machines tend to be more cost-efficient while benchtop models usually require more of an upfront investment but provide long-term value in heavy duty applications – however when aligned with workflow volume and environment your decision could lead to the ideal VIN marking machine selection for your business.

Recommended Products