Why CO2 Laser Engravers Are the Best Choice for Wood Marking

Laser technology has revolutionized the industry of modern woodworking, offering a versatile and effective solution for marking and engraving wood. Among the various laser types available, CO2 lasers have emerged as the preferred choice for numerous applications. Laser engraver expert Zixu explores why CO2 laser engravers are the ideal tool for wood marking, exploring their diverse applications, technical intricacies, and compelling benefits.

Versatile Applications of CO2 Laser Engravers in Wood Processing

CO2 laser engravers have revolutionized the woodworking industry, offering a wide range of applications beyond traditional marking techniques. Here are some of the most common uses of CO2 lasers in wood processing:

- Precision Marking: CO2 lasers excel at creating intricate and detailed markings on wood surfaces. From simple text and barcodes to complex logos and QR codes, these machines can produce high-quality markings with exceptional precision. This makes them ideal for applications such as date codes, batch numbers, and personalized engravings.

- Intricate Engraving: Beyond basic marking, CO2 lasers can be used to create stunningly detailed engravings on wood. Whether you’re crafting intricate patterns, creating raised reliefs, or producing 3D effects, CO2 lasers offer unparalleled versatility and precision. This makes them a popular choice for producing high-quality wooden crafts, gifts, and decorative items.

- Precise Cutting: CO2 lasers can effortlessly cut through wood, producing clean and precise edges. This makes them ideal for cutting out complex shapes, intricate designs, and delicate patterns that would be difficult or impossible to achieve with traditional cutting tools. Laser cutting also eliminates the need for time-consuming finishing processes, resulting in significant time and cost savings.

- Intricate Hollowing: CO2 lasers can be used to create intricate hollowed-out designs on wood surfaces, which is commonly used to produce decorative elements such as fretwork panels, decorative screens, and custom-shaped wooden signs.

Technical Details of CO2 Laser Engraving for Wood Processing

CO2 laser marking machines have become indispensable tools in the woodworking industry, offering precise and efficient processing capabilities. Here, we delve into the specific technical details that make CO2 lasers so effective for wood applications.

- Laser Wavelength: CO2 lasers typically operate at a wavelength of 10.6 micrometers, which is highly absorbed by non-metallic materials like wood. This specific wavelength ensures efficient energy transfer and optimal marking results.

- Power Range: The power output of CO2 lasers can be adjusted to suit various wood types and processing requirements. From low-power systems for delicate engravings to high-power machines for rapid cutting, there is a CO2 laser solution to fit every need.

- Marking Speed: CO2 lasers are renowned for their high marking speeds, with some models capable of processing up to 7000 mm/s. This makes them ideal for high-volume production environments where efficiency is paramount.

- Precision: CO2 lasers offer exceptional precision, capable of producing markings with a minimum line width of 0.1mm. This level of detail ensures that even the most intricate designs can be accurately reproduced on wood surfaces.

Benefits of Choosing a CO2 Laser Engraver as a Wood Laser Marking Machine

CO2 laser engravers offer exceptional capabilities for marking wood products with remarkable precision. Capable of achieving a marking resolution of approximately 0.1mm, these machines can effortlessly handle the intricate demands of most wood marking applications. From delicate engravings of complex patterns, to clear and readable text, and even high-density QR codes, CO2 lasers provide unmatched versatility.

One of the standout features of CO2 laser engraving on wood is its adaptability. By precisely adjusting the laser power, operators can tailor the marking process to suit various wood types and hardness levels, ensuring optimal results. This flexibility allows for consistent and high-quality markings across a wide range of wooden materials, from softwoods to hardwoods.

Key benefits of using CO2 laser engravers as a Wood Laser Marking Machine:

- Permanent Marking: CO2 laser marking machines create permanent marks on wood surfaces that are highly resistant to fading or wearing away due to environmental factors. This ensures that the markings remain clear and legible for an extended period, making them ideal for applications requiring long-lasting identification.

- Non-Contact Processing: Unlike traditional marking methods, laser processing is entirely non-contact. This eliminates the risk of inducing internal stress in the wood, preserving the workpiece’s original precision and integrity.

- High-Precision Marking: CO2 laser marking machines can achieve extremely fine marking details, with a minimum line width as narrow as 0.1mm. This level of precision enables the creation of intricate designs and fine text on wood surfaces, making them suitable for applications that demand high aesthetic quality.

- Wide Range of Applications: While CO2 laser engravers are particularly well-suited for wood, they can also be used to mark a variety of non-metallic materials. This versatility makes them a valuable asset in diverse manufacturing environments.

- Low Operating Costs: CO2 laser marking machines offer a cost-effective solution for wood processing. The ability to produce markings in a single pass, combined with high speed and low energy consumption, reduces overall operating costs. Additionally, the absence of consumable materials further minimizes expenses.

- High Processing Efficiency: Controlled by industrial computers, CO2 laser beams move at high speeds, enabling rapid marking and significantly increasing production efficiency. This is particularly beneficial for high-volume manufacturing applications.

- Fast Design and Editing: The seamless integration of laser technology with computer software allows for real-time editing of marking information. This flexibility enables quick adaptation to different product batches and customization requirements.

- Adjustable Depth Control: CO2 laser marking machines provide precise control over the depth of engraving. This feature allows for the creation of both shallow surface markings and deep engravings, catering to a wide range of application needs.

By combining these advantages, CO2 laser engravers offer a compelling solution for wood marking, providing manufacturers with a versatile, efficient, and cost-effective tool for producing high-quality, customized products.

The Indispensable Role of CO2 Laser Engravers in Woodworking

CO2 laser engravers have solidified their position as indispensable assets in the woodworking industry. Their versatility, precision, efficiency, and durability make them the preferred choice for a wide range of applications. From intricate designs and personalized markings to mass production and industrial engraving, CO2 lasers deliver exceptional results.

If you are looking for a suitable wood laser marking machine, please boldly choose CO2 laser engraver. If you are hesitating about which company to choose CO2 laser engraver, please choose the laser marking machine supplier Zixu as your partner, we will provide you with the best CO2 Laser Marking Machine.

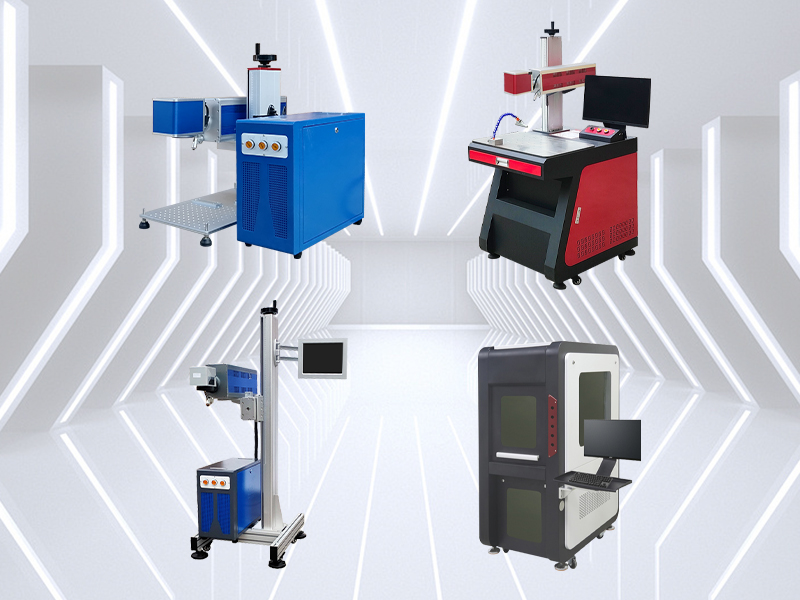

Recommended Products