Wood Laser Marking Most Common Applications

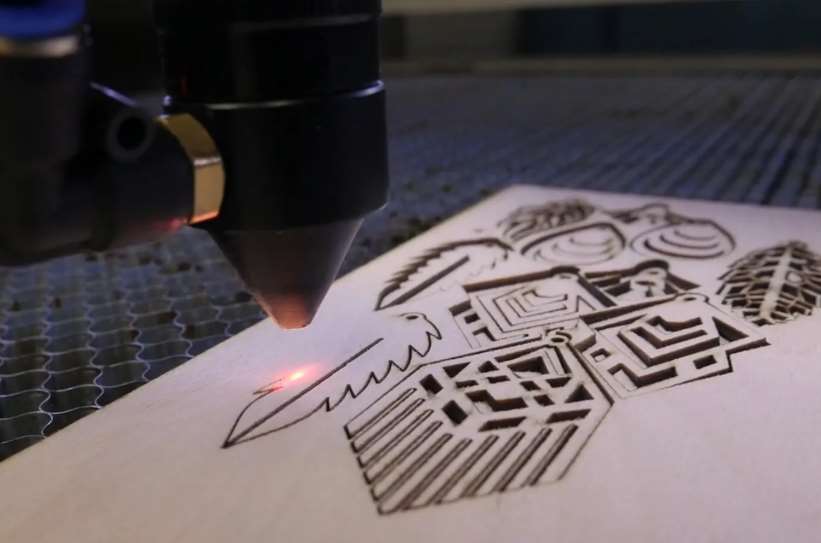

Wood laser marking has quickly become a go-to method for artists, manufacturers and DIY enthusiasts who seek to etch precise and permanent designs onto wood surfaces. Thanks to laser technology’s versatility and efficiency, laser marking machines are not only efficient but suitable for a range of uses; whether branding products or personalizing gifts – laser marking on wood offers unparalleled quality!

Can Laser Marking on Wood?

Yes, laser marking on wood is both practical and widely utilized across numerous industries. The process involves using a focused laser beam to burn, engrave or discolor the surface of wood without physical contact and create permanent markings – producing clean results whether working on mass production runs or creating one-off pieces for customers.

Wood can react differently to laser marking. Lighter woods such as maple, birch and basswood tend to show greater contrast and detail – perfect for intricate designs. Meanwhile, denser or resin-rich varieties like oak or pine require adjustments in laser settings in order to avoid excess charring or uneven lines.

No matter if it’s logos, decorative patterns, text or any combination thereof – laser marking offers excellent control and repeatability when adding logos, decorative patterns or text to wood surfaces. With the proper equipment and techniques in place, wood laser marking becomes an invaluable resource both artistic and industrial uses alike.

Common Applications of Wood Laser Marking

Laser wood marking offers unmatched versatility and precision for use across a range of applications – here are four major uses.

Gifts & Custom Decorations

Laser marking is increasingly being utilized as an efficient means to craft personalized gifts and decorations that stand out. Due to the intricate, custom designs it produces for both individuals and businesses alike, items like photo frames, wooden jewelry boxes, cutting boards, and coasters are popular products used with this process.

Laser marking makes an excellent way to mark names, dates, quotes, or images on wood surfaces for weddings, anniversaries, birthdays, or holiday gifts. Lasers ensure sharp text and images even on uneven or curved surfaces for an impressive professional finish that gives each piece its own special character and distinction.

Branding and Packaging

Laser marking plays an essential part in product branding and packaging, offering an efficient yet permanent way to mark wooden products with logos, brand names, QR codes, or labels containing such designs. Many businesses utilize laser marking technology for logo engraving on wooden packaging boxes or labels for added brand identification purposes.

Laser marking offers superior and more lasting printing methods; unlike conventional methods, it creates high-quality results that won’t fade, rub off, or smear over time – an invaluable feature when applied to luxury packaging where aesthetics is of equal importance and precise placement of logos or designs is critical. This method makes laser marking ideal for companies wishing to keep their brand identity intact for extended use.

Laser marking technology provides another useful application: serializing products or manufacturing dates can make tracking them and maintaining high-quality standards much simpler.

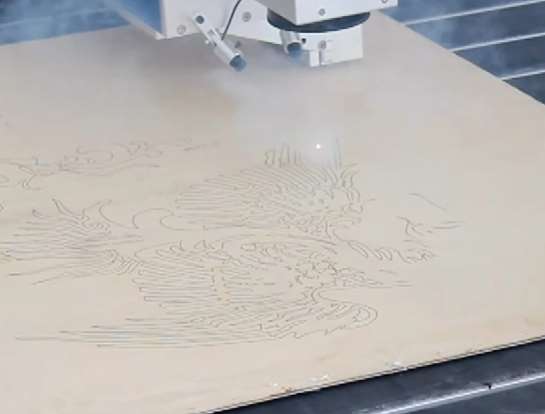

Signage and Decorative Displays

Wooden signs and decorative displays benefit immensely from laser marking’s high precision and versatility, whether used as business signs, directional boards, or home decor items – laser marking provides a permanent solution that’s both attractive and cost-effective to add text, logos, or intricate designs into their displays.

Laser marking can be utilized both indoors and outdoors for signage purposes, with businesses often employing wooden plaques, address signs, and nameplates engraved using laser marking to enhance their branding efforts. Laser engraving ensures text or designs remain legible even at large or small sizes; in addition, decorative wooden displays such as wall art, clock, or even three-dimensional sculptures may also be created using this form of marking, allowing endless opportunities for customization and creativity.

These applications illustrate the wide-ranging applications for wood laser marking. No matter whether it is being utilized by hobbyists, small businesses, or large enterprises, laser marking provides endless opportunities for elevating wooden products!

Tips about Wood Laser Marking

To achieve high-quality, consistent results when laser marking wood, follow these best practices:

| Factor | Recommendation | Why It Matters |

| Wood Selection | Use hardwoods (oak, cherry, walnut) for dark, crisp engravings. Softwoods (pine, cedar) work but may produce lighter marks. Avoid resin-heavy woods to prevent excessive burning. | Different woods react differently to lasers, affecting contrast and depth. |

| Laser Settings | Test power (10-80%), speed (100-1000 mm/s), and frequency (500-20,000 Hz) on scrap wood first. Higher power = deeper engraving; lower speed = darker marks. | Prevents overburning or weak engravings. |

| Focus & Alignment | Ensure the laser is properly focused. Use a calibration tool if necessary. | Improves precision and detail clarity. |

| Surface Preparation | Sand the wood lightly before engraving. Apply masking tape for lighter woods to reduce scorch marks. | Reduces uneven burns and residue. |

| Ventilation & Safety | Use an air assist or exhaust system to remove smoke and debris. Wear protective eyewear. | Prevents health hazards and keeps the workspace clean. |

| Post-Processing | Wipe the engraved area with a damp cloth or use light sanding to remove residue. Apply wood oil or wax for a polished finish. | Enhances appearance and durability. |

Always perform a test run on a small section of the wood to fine-tune settings before full-scale engraving.

Wood Laser Marking Machines

Selecting an effective laser machine for wood engraving depends upon your project requirements.

- CO2 laser marking machines are among the most versatile choices available and provide versatile marking and cutting wood capabilities; these lasers work great on softwoods like pine as well as hardwoods like oak while producing deep engravings or fine details with equal success.

- Fiber laser marking machines may not be commonly found for wood use but can create high-contrast surface marks perfect for branding and barcodes, though these lasers tend to perform best on metals and plastics.

- Diode laser marking machines offer hobbyists and small businesses an economical solution for light engraving on thin wood, plywood or MDF surfaces. Although less powerful than CO2 lasers, diode lasers excel in light applications like thin wood engraving.

- UV laser marking machines offer ultra-fine detailing with minimal burning, perfect for intricate wood designs with intricate intricacies.

Key factors when choosing a machine include power (10W to 100W+), work area size, software compatibility and cooling systems. High-power CO2 lasers are best suited for industrial uses while desktop or diode CO2 lasers may work for smaller-scale projects.

Are you seeking personalized suggestions tailored specifically to your budget and application?

Contact Zixu, we will serve you the best suggestion!

Recommended Products